Choosing the right tool for cutting thick polyester fiberboard is like choosing between a heavy-duty truck and a sports car. Both get the job done, but in very different ways. When choosing between pneumatic and electric vibratory tools, understanding their strengths and limitations will help you make the right decision for your project.

Pneumatic vibratory tools are ideal for cutting thicker, denser panels (24-50 mm) due to their greater power. Electric vibratory tools, on the other hand, excel in speed and precision, especially when dealing with thinner panels (9-12 mm). Each tool has its specific application, but they can also be used together to cover a wide range of material thicknesses.

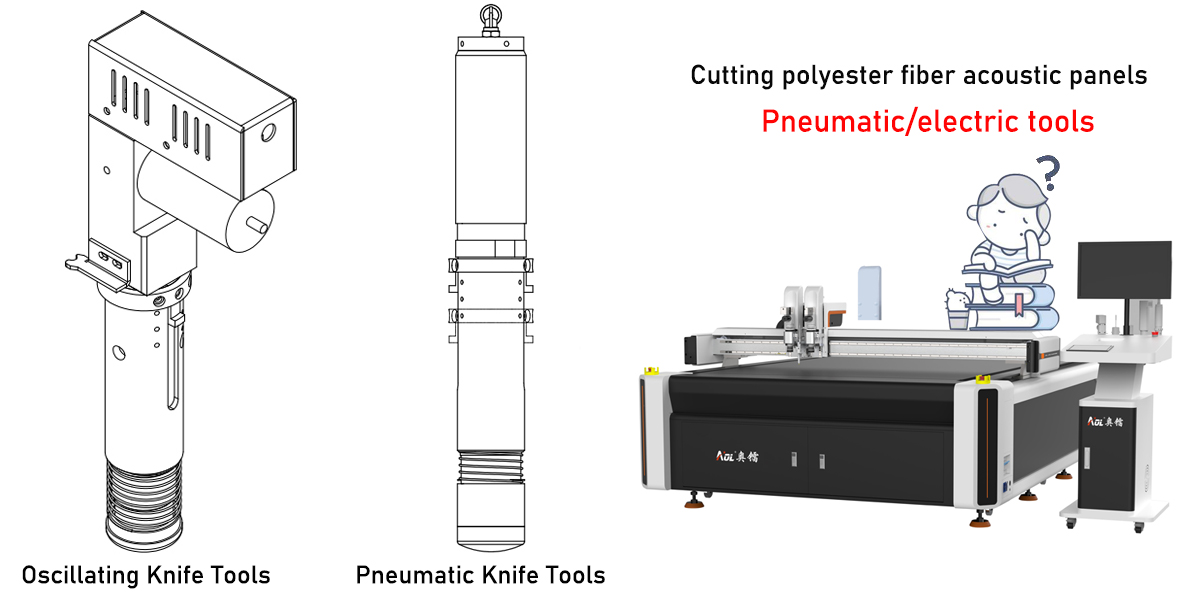

Here´s how these two tools work:

Pneumatic vibration tool: Use compressed air to drive the piston to reciprocate, generate high-frequency vibration, and drive the cutting blade to cut.

Electric vibration tool: The motor drives the eccentric wheel to rotate, generate vibration, and drive the cutting blade to cut.

When it comes to cutting thicker polyester panels, the pneumatic oscillating tool is the clear winner. Its compressed air system delivers more power, allowing it to handle thicker, denser materials. If you’re dealing with panels that require deeper cuts or multiple layers, a pneumatic tool can give you the power you need to get the job done without a hitch.

Electric vibratory tools, while effective for thinner panels, are not as powerful. Their advantage is precision and speed with less dense materials, making them better suited for thinner panels where control is more important than brute force.

Choose the most cost-effective tool according to actual needs. For example, if the cutting volume is not large but the requirements are high, you can choose an electric tool with better performance; if the cutting volume is large and the requirements are not high, you can choose an economical pneumatic tool.

Which tool is easier and more convenient to maintain?

In the long run, electric vibration tools have the advantage of lower maintenance costs. Since they do not require an air compressor or complex pneumatic systems, they have fewer moving parts and therefore lower maintenance costs. Electric tools are generally easier and cheaper to repair, so it is a more cost-effective choice in the long run.

While powerful, pneumatic tools require more frequent maintenance, especially air compressor systems. If not properly maintained, these systems can cause production downtime, which can be costly. However, if you primarily work with thicker materials, the extra maintenance may be worth it at the expense of the power and efficiency that pneumatic tools offer.

Pneumatic and electric vibration tools each have their own advantages and disadvantages, and choosing the right tool requires comprehensive consideration based on actual needs. I hope this article can help you better understand these two tools and make a more informed choice when cutting polyester fiber acoustic panels.

I believe you have made some choices about how to choose through this article. If you still have questions or want to know more about the cutting machine, please click here to contact us! We will answer you as soon as possible.

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109