The textile industry has always been one of the most dynamic, evolving to meet the growing demand for speed, precision and cost-effectiveness. In recent years, technology has played a vital role in revolutionizing the way textiles are cut, and one innovation in particular stands out: the CNC fabric cutting machine. As manufacturers and designers alike strive for greater efficiency, it is important to explore whether CNC fabric cutting machines can truly lead the future of textile cutting.

What is a CNC fabric cutting machine?

CNC fabric cutting machines use computer technology to automate the fabric cutting process, which traditionally requires a lot of manual work. The machine is equipped with sharp blades and cutters, which are precisely controlled by a computer, allowing it to cut fabric with great precision and speed. Compared with traditional fabric cutting methods, fabric cutting machines can simplify operations, reduce material waste, and improve production quality.

The evolution of fabric cutting machines

Cutting fabric has always been a highly manual process. Clothing manufacturers and textile mills typically rely on skilled workers to cut fabric by hand, which is precise but slow and can result in a lot of material waste. As demand for faster production cycles and tighter quality control continues to grow, the industry is turning to more automated solutions.

One of the earliest advances was the introduction of cloth cutting machines, which were able to cut cloth faster and more accurately than manual methods. These machines were often limited in their capabilities, often required more operator intervention, were slower than modern systems, and lacked the precision required in today’s competitive textile industry.

However, the advent of CNC technology marked a revolutionary shift in the capabilities of fabric cutting machines. Today’s CNC fabric cutting machines can not only follow complex cutting patterns, but can also accommodate variations in fabric types and thicknesses, providing manufacturers with a high degree of flexibility.

How CNC Fabric Cutting Machines Are Changing the Industry

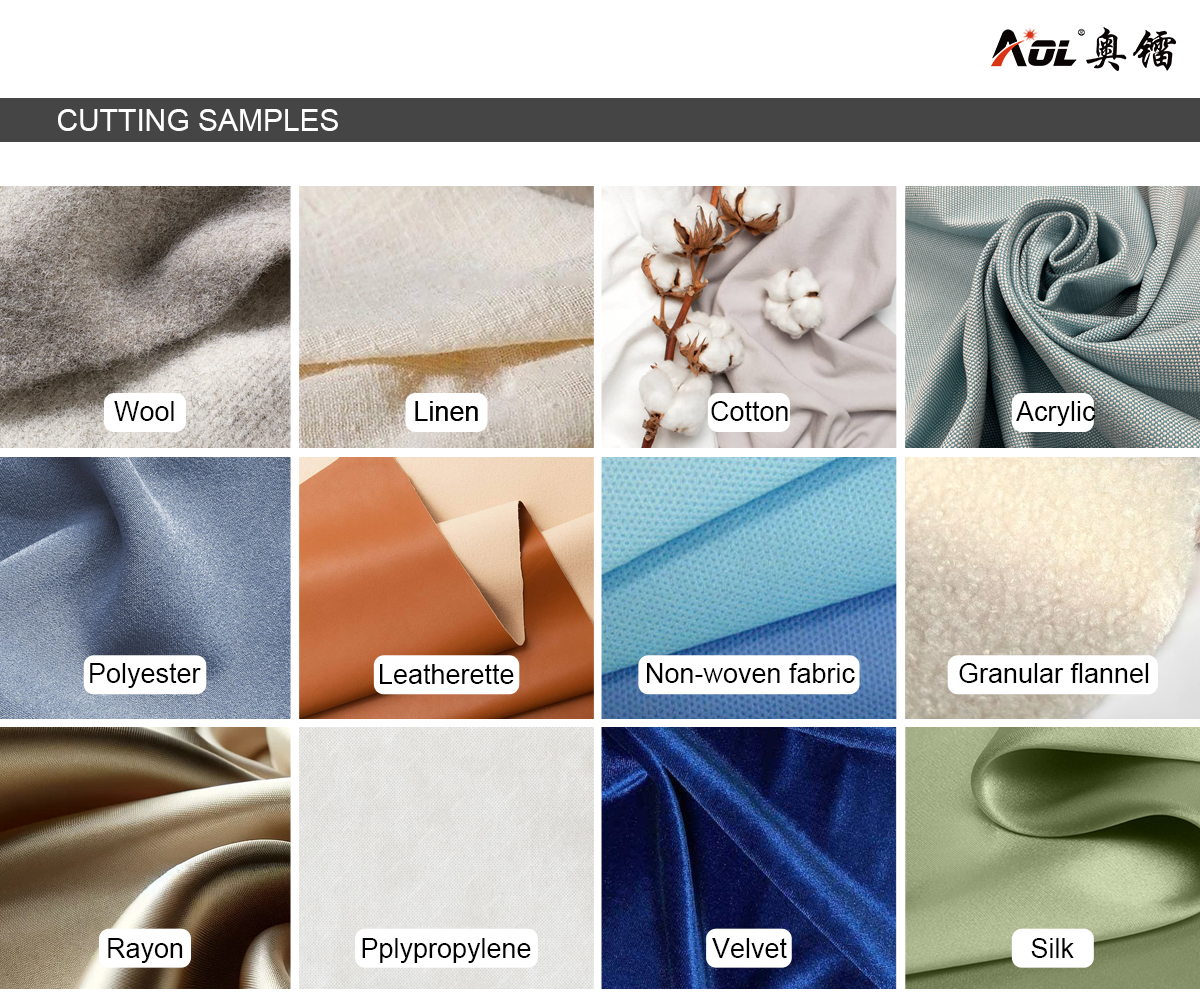

CNC fabric cutting machines are profoundly impacting the textile industry, revolutionizing the way companies cut fabric. These machines work with a wide range of fabrics, including cotton, silk, polyester, wool, and more, allowing manufacturers to produce a wide range of textiles more efficiently.

One of the main benefits of CNC fabric cutting machines is their precision. These machines are able to cut complex patterns with millimeter-level accuracy, reducing the need for post-production corrections. This level of precision ensures that clothing cutters can maintain consistent quality even when working with complex or custom designs.

Using a CNC fabric cutting machine can significantly reduce labor costs. With fewer manual steps involved, manufacturers can reduce their reliance on skilled labor. Integrating a CNC fabric cutting machine into a production line can increase automation, further reducing operating costs and increasing overall productivity.

What are the advantages compared to traditional fabric cutting machines?

Speed and Efficiency

CNC fabric cutting machines work much faster than manual cutting machines. By automating the cutting process, manufacturers can complete projects faster, thereby reducing production time and increasing output.

Support table height cruise

Can detect and save the flatness of the table, and can automatically adjust the knife depth according to the detected flatness of the cutting table during the cutting process to ensure the accuracy of the cutting.

Reduce material waste

The precision cutting ability of CNC fabric cutting machines helps minimize material waste, which is a key factor in improving cost-effectiveness. Traditional fabric cutting machines often cause waste, especially when dealing with complex patterns or when the cutting accuracy is unstable.

Cost Savings

While the initial investment of CNC fabric cutting machines may be high, their long-term benefits are significant. Over time, reduced labor costs, increased speed, and reduced material waste will bring greater overall cost savings to manufacturers.

Customization and Flexibility

CNC fabric cutting machines have greater flexibility in cutting a variety of fabrics. Whether the fabric is delicate or tough, CNC machines can be programmed to adjust their cutting methods, providing manufacturers with greater flexibility.

The impact of CNC fabric cutting machines on clothing cutting machines

Garment cutting machines are used to cut fabric into specific shapes for garment production, and they have benefited greatly from the advancement of CNC fabric cutting machines. CNC technology enables garment cutting machines to handle a variety of fabric types and garment designs more efficiently, accurately, and flexibly.

With the introduction of CNC fabric cutting machines, garment cutting machines are now able to work seamlessly with digital design files, thereby improving the speed and accuracy of the cutting process. This automated technology reduces the possibility of errors in the cutting process, ensuring that each garment is cut to the exact specifications of the design.

If you are looking for an efficient, accurate, and stable fabric cutting device, CNC fabric cutting machines are undoubtedly your best choice. Feel free to contact us for more product details and customized solutions. We will provide you with professional technical support and quality after-sales service.

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109