For companies in the textile and interior decoration industries, purchasing a CNC carpet and curtain cutting machine is a significant capital investment.

Choosing the right CNC carpet and curtain cutting machine doesn't begin with the machine itself, but with a deep understanding of the material it will be cutting. The interaction between the cutting blade and the textile is at the heart of the entire operation.

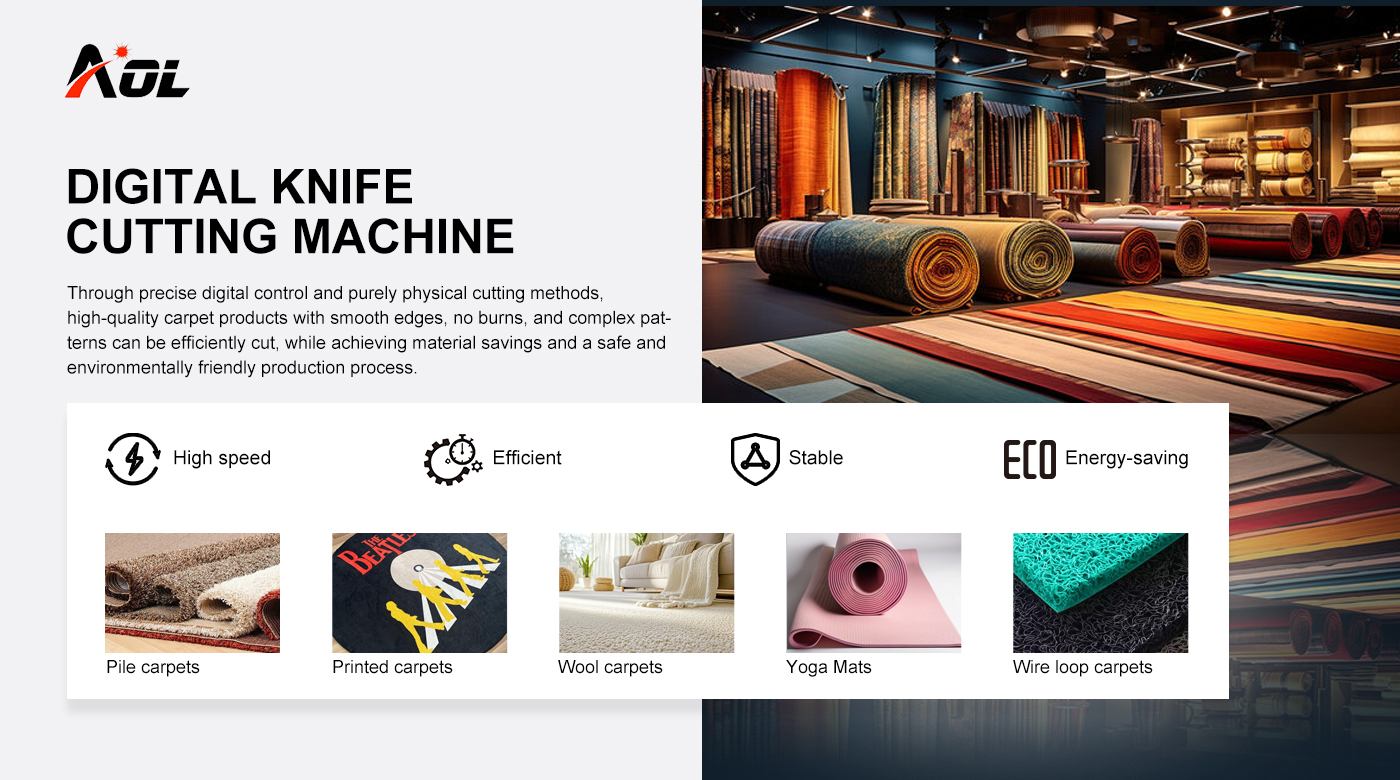

The differences in carpets mainly depend on the pile fibers, structure, and backing material. Natural fibers such as wool are soft and elastic, but are easily pulled by dull blades when cut; synthetic fibers such as nylon, polyester, and polypropylene are more wear-resistant and stain-resistant, but should be avoided when cutting at high temperatures. Different structures (loop pile, cut pile, or blends) require different levels of blade sharpness, with loop pile types being particularly prone to snagging. Backing materials such as jute, polypropylene, or foam rubber also affect the cutting method; rigid backings require more pressure, while soft backings are easily compressed or torn.

Curtain fabrics come in a wide variety, from lightweight tulle and organza to heavy velvet, brocade, and blackout fabrics, each presenting different cutting challenges. Tulle is prone to shifting and wrinkling, requiring the use of vacuum suction or other pressing devices; velvet cutting requires maintaining a consistent pile direction to avoid color differences; blackout fabrics have a composite structure, demanding clean, wrinkle-free cuts to maintain their light-blocking properties; and different weaves (such as plain weave and jacquard) also affect cutting precision and results.

Cutting this type of material typically requires a vibrating knife, a drag blade, and a rotating blade.

The vibrating cutter (EOT) is a high-efficiency tool designed specifically for cutting thick, soft materials. Through thousands of high-speed reciprocating motions per minute, it achieves clean, flat cuts, preventing materials from being flattened or deformed. It is particularly suitable for cutting high-pile carpets, foam-backed carpets, and multi-layered fabrics, and is a core technology of multi-functional cutting systems in the modern home furnishing and soft furnishing industry.

A drag cutter (UCT) is a simple and fast cutting tool, similar to a plotter pen, that cuts by dragging. It is suitable for thin and uniform materials such as vinyl flooring and non-elastic curtain fabric. However, its tip lag makes it difficult to cut sharp angles directly, and it can also pull fibers when processing fibrous materials, affecting cutting accuracy.

Rotary cutting blades (DRT) cut fibers by rolling, achieving smooth cuts with minimal pressure and avoiding stretching and wrinkling of delicate fabrics such as tulle. This makes them particularly suitable for long, straight cuts, such as large curtains. However, their efficiency decreases with fabric thickness and they are less effective at handling complex patterns. For carpet and curtain manufacturers, modular CNC cutting machines with interchangeable oscillating and rotary cutting heads offer the ideal flexibility.

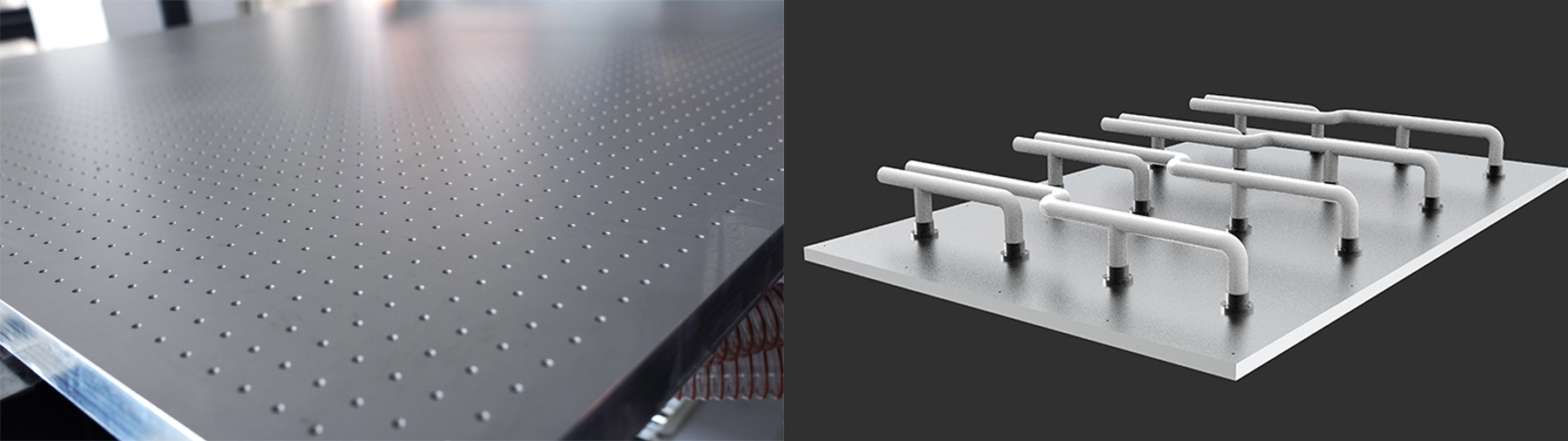

If the material moves during the cutting process, even the most precise cutting tools cannot guarantee accuracy. Therefore, high-performance CNC carpet and curtain cutting machines must be equipped with a powerful vacuum system. The cutting table is covered with micropores, and a vacuum pump adsorbs the material, keeping it firmly attached to the table surface and ensuring a precise and stable cut.

Large cutting tables don't need to maintain a constant vacuum across the entire surface, as that would result in enormous energy waste. High-end machines divide the cutting table into multiple zones, each of which can be turned on or off independently. This allows you to concentrate the full power of the vacuum on a specific area containing the material, providing maximum suction while saving electricity. Imagine cutting a small rug on a massive 10-meter cutting table; the zoning function lets you activate only the 2 to 3 square meters you actually need.

Some people may have questions about cutting speed, so here are the answers: Effective cutting speed depends on several factors:

Material limitations: Thick carpets cannot be cut at the same speed as thin fabrics. The material itself determines the maximum speed at which high-quality cuts can be achieved without scorching, melting, or deforming the textile.

Tool type: As mentioned earlier, different tools have different optimal speeds. A drag tool moves very fast in a straight line, while a reciprocating tool, due to its vertical motion, will inevitably be slower.

Pattern complexity: This is the most critical factor. A machine's ability to maintain speed on curves and sharp turns depends on its acceleration and deceleration capabilities. Patterns containing many complex details and small radii force even the fastest machines to slow down significantly to maintain accuracy. Machines with high acceleration can complete these complex paths faster and more efficiently than those with sluggish power.

So, how do you determine your speed requirements? One effective method is to conduct a time study of your current manual cutting process. How long does it take your most skilled cutter to complete a representative product sample? This can serve as a benchmark. When evaluating CNC machine tools, ask for a demonstration of it cutting your own design files. Record the time for the entire process, from loading the file to completing the final cut. This kind of real-world testing result is far more valuable than any specifications in the product manual.

Frequently Asked Questions (FAQ):

What are the main differences between a CNC cutting machine for carpets and a CNC cutting machine for curtains?

While a multi-functional machine can typically handle both carpet and curtain cutting simultaneously, the key difference lies in the optimal blades and material handling. Carpet cutting usually requires powerful reciprocating blades to work with thick, dense backings. Curtain cutting, especially when cutting delicate fabrics, is better suited to rotating blades, preventing stretching and abrasion. Ideally, a machine suitable for both applications should be equipped with interchangeable blades.

How much space do I need to house my CNC carpet and curtain cutting machine?

In addition to the machine's cutting area, you also need to consider other aspects. A safe rule of thumb is to leave at least 1-1.5 meters (3-5 feet) of clearance around the machine for operator access, loading and unloading, and maintenance. If the machine has a conveyor belt, even more space needs to be reserved in front of and behind the machine for material conveying and collection.

What is the learning curve for operating a CNC cutting machine?

Modern CNC machine tools are designed with user-friendly interfaces. People with basic computer skills can usually master the basic operations with just a few days of high-quality training. However, mastering advanced functions, software details, and optimized settings for new materials requires more time and experience. The quality of the initial training provided by the supplier is a key factor in shortening the learning curve.

Are reciprocating cutting tools noisy when they are running?

Because reciprocating cutting tools have a higher mechanical motion frequency, they are indeed noisier than drag-and-drop or rotating cutting tools. While noise levels are generally within acceptable industrial limits, it is still a factor to consider for your workshop environment. Suppliers can provide decibel levels for their machines, and we always recommend that you personally inspect and listen to the machine's operation whenever possible.

How much waste can automated nesting software actually save?

Cost savings largely depend on the complexity of the cut shapes and how they are arranged. For simple rectangular cuts, the savings are negligible. However, for complex, irregular shapes such as custom upholstery or patterned carpets, automated layout can typically reduce material waste by 5% to 15% compared to manual layout. If thousands of meters of expensive material are used, this translates to very considerable cost savings.

The CNC carpet and curtain material cutting all-in-one machine, with its precision, efficiency, flexibility, and intelligence, is becoming an indispensable production tool in the interior design industry. It provides a completely new solution for carpet and curtain cutting, enabling manufacturers to achieve higher efficiency and quality in a highly competitive market.

If you would like to know the price and more details, please click here and fill in your information. We will answer your questions as soon as possible!

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109