High-end leather cutting machine is a high-precision CNC cutting equipment designed for natural leather and genuine leather materials. It is widely used in automotive interiors, furniture sofas, luxury shoes and bags, high-end clothing and other fields. The equipment combines visual positioning system, intelligent typesetting system and multi-functional vibration cutter head to achieve accurate, efficient and non-destructive cutting of special-shaped leather materials, comprehensively improving production efficiency and material utilization.

The industry pain points in leather cutting are as follows:

1. The efficiency of manual defect avoidance calculation and layout is too low

2. The efficiency of manual drawing and cutting is low and non-standard

3. The layout requirements are diversified, and the order requirements are getting higher and higher

4. There are many types of leather materials and cut pieces, and the manual management is chaotic

5. The utilization rate of raw materials for manual layout is too low

6. The technical requirements for cutting personnel are very high, it is difficult to recruit workers, and the salary is high

7. The leather cutting, punching, and marking processes are cumbersome

To solve the above-mentioned pain points, AOL customized high-end leather CNC cutting machine has the following solutions:

1. Intelligent typesetting, automatic cutting, high efficiency, stable quality, high and consistent material utilization.

2. Newcomers can get started quickly, training is simple, work intensity is low, recruitment is easy, and it saves a lot of personnel and management is easy.

3. Digital management of templates, convenient retrieval, fast production, and flexible response to personalized orders; forming unified technical standards, production and management methods to meet the needs of rapid expansion and off-site factory development.

4. Digital management of leather materials, precise cost control, and reduction of disputes between factories and leather suppliers.

5. Connect with enterprise system data, real-time data feedback, provide leadership with real information and make quick decisions.

What are the advantages of customizing high-end leather CNC cutting machines?

01 Intelligent cutting production line

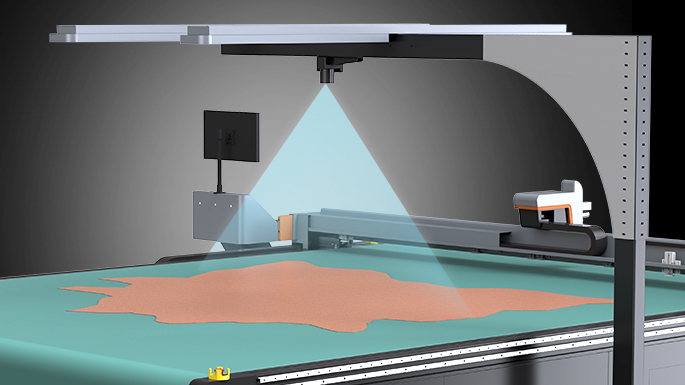

The whole process of leather contour scanning-grading layout-cutting is completed continuously on one machine, which can minimize manual operation and reduce dependence on professionals.

02 Continuous processing, saving time

Scanning and cutting dual-zone bidirectional transmission. Scanning and layout in the back, cutting and feeding in the front, working at the same time.

Cutting, punching, and marking are integrated into one, reducing the production process and achieving faster order delivery.

03 Vacuum adsorption system

48 vacuum partitions, tracking adsorption, effectively ensuring material flatness and improving cutting accuracy

04 Obstacle automatic detection function

Automatically stop when obstacles are detected in the cutting area to ensure human-machine safety

05 Dual-screen display

The computer screen can be expanded, and the layout progress and cutting progress can be displayed on the split screen, saving switching frequency and improving operation efficiency

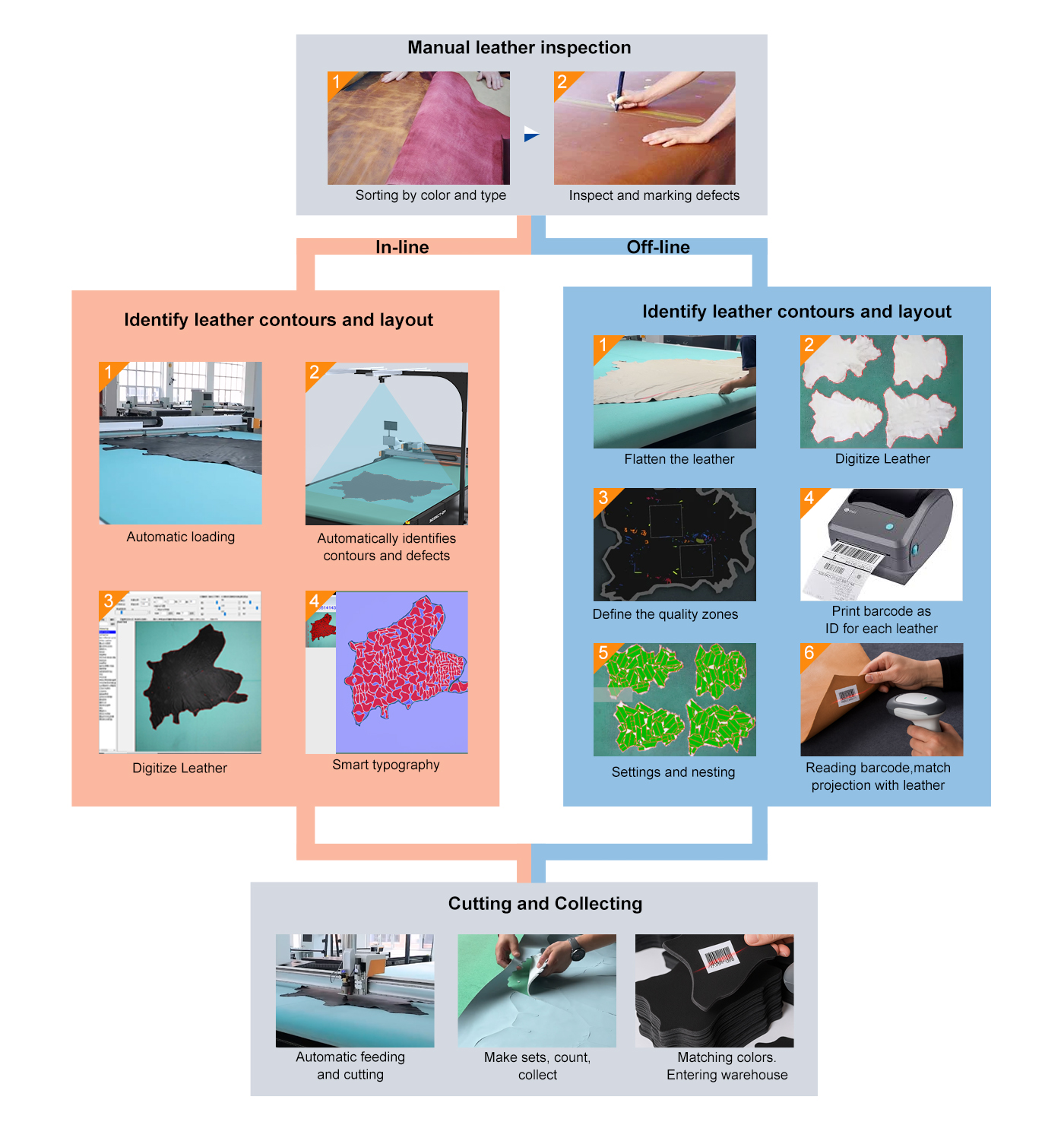

Our customized high-end leather digitization has online/offline modes, the specific process is as follows:

Inline Solutions

Inline or inline CNC leather cutting means that all operations are performed on the main machine.

Option 1 – Inline: The camera and projector are mounted on a gantry above the machine. Cutting and unloading are done on the same machine. This reduces overall costs and floor space, making it ideal for small and medium-sized businesses.

Option 2 – Inline: For larger businesses or users who need to cut leather in batches, the system can be expanded to include dedicated scanning and unloading stations. This means that while the first piece of leather is being cut, the second piece of leather can be scanned and prepared for cutting. Once the first piece of leather has been cut, the leather moves to the (optional) unloading area, where the second piece of leather is cut, the third piece of leather is scanned, and so on.

Offline solution

Offline leather cutting is suitable for companies that need to cut large quantities of leather as quickly as possible.

This innovative solution consists of a separate scanning station. The scanning station is separated from the cutting machine.

The leather is scanned and advanced software is used to mark and detect any defects.

The software nests a template around the defects.

A barcode is generated and attached to each hide.

The hides are then stored waiting to be cut.

As each hide is put into the CNC leather cutting machine, the barcode is scanned. This calls up all the cutting information associated with that hide. No other action is required on the machine.

The hides are then cut, unloaded and sorted.

The separation of the processes ensures that both the scanning station and the leather cutting CNC machine can operate efficiently. Using a double bridge on the cutting machine can further speed up production.

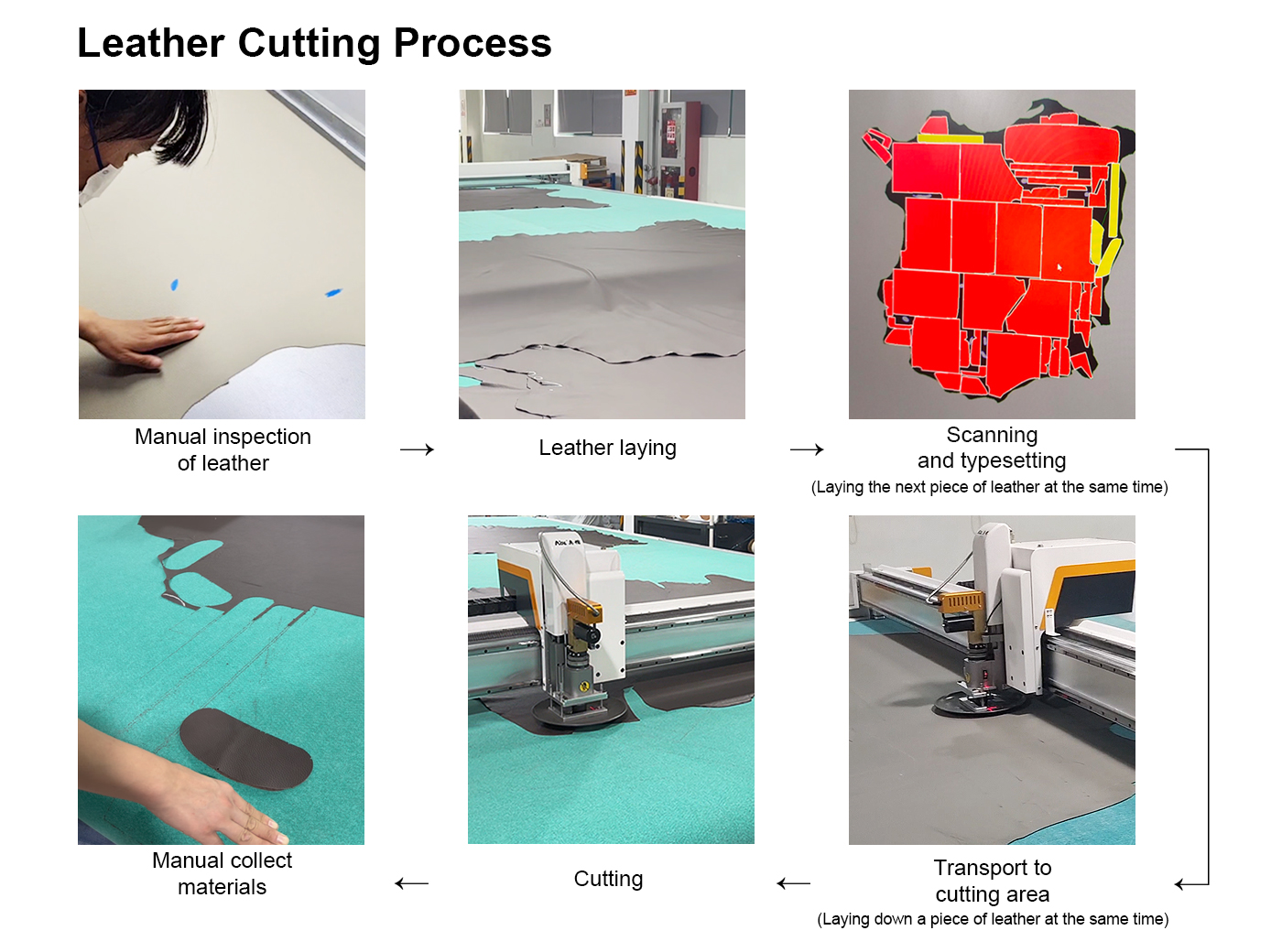

What is the workflow of customizing a high-end leather CNC cutting machine?

Manual leather inspection → laying out → camera identification of contours and defects → intelligent layout → transport to cutting area (laying out the next leather at the same time) → cutting (laying out the next layout at the same time) → manual material collection

Investing in custom high-end leather CNC cutting machines brings six benefits to customers:

1. Shorter delivery time, reducing various wastes caused by a large number of intermediate warehouses in traditional production methods;

2. Improve production efficiency, reduce the scale of employment, realize multiple rounds of orders, and speed up the speed from cutting to sewing to forming;

3. Control the amount, save material costs, reduce refills, and ensure delivery time;

4. Reduce cutting dies, facilitate the response to flexible orders with various changes, and reduce the waste of cutting dies for trial products, development proofing, product trial sales samples, product confirmation samples, and small order products;

5. Better quality and high stability, more conducive to the popularization of computer sewing machines in the next process, and more obvious savings in comprehensive calculation (cutting + sewing) costs;

6. Data-based/visualized production management improves factory management level and corporate image.

What are the technologically advanced research and developments in high-end leather CNC cutting machines?

Leather scanning and recognition technology

The leather array camera scanning technology can scan the leather's defects, contours, area data, etc., and can quickly and clearly digitize the leather.

Pattern visual recognition technology

The newly developed visual recognition technology can visually identify the pattern in the cutting parts, extract features, accurately identify and intelligently cut.

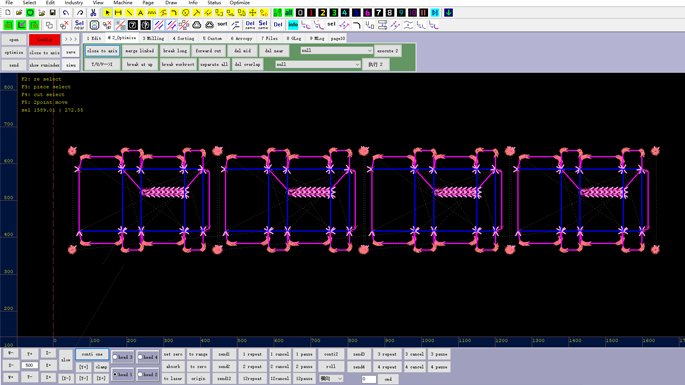

Leather intelligent typesetting technology

The unique fully automatic leather typesetting technology saves 90% of time compared to manual typesetting, and can increase the leather utilization rate by 1%~6% compared to manual typesetting.

Five-matching genuine leather typesetting technology

In response to the leather color matching/pattern matching needs of shoes, the latest developed intelligent typesetting technology can realize intelligent double typesetting, comparable to the typesetting experience of skilled workers, and achieve industry application breakthroughs.

Dual contour typesetting technology

This technology can improve the leather typesetting utilization rate on the basis of effectively controlling the cutting yield by setting the contour edge of the leather in different levels; setting the typesetting knife distance at different locations on the edge of the internal parts.

High-speed knife bar

Unique CNC acceleration computing technology, which is more than 15% faster than ordinary similar models, improves production efficiency.

Variable frequency energy-saving technology

Unique energy-saving technology, which saves 30% energy than ordinary similar models.

Automatic knife setting technology

Automatic knife setting technology for intelligent cutting machines. By installing the knife setting structure, the software can quickly and automatically correct the knife reference after replacing the blade, saving manual correction time, reducing human operation errors, effectively extending the service life of the cutting mat and improving work efficiency.

Multi-layer fine cutting technology

The internationally leading multi-layer cutting technology can cut sponges within 40 mm, fluffy materials within 25 mm, and solid multi-layer flexible materials within 10 mm.

Multi-function piece picking technology

It can project and display on the leather after cutting: multiple piece inspection methods such as the same part, the same number of yards, the same even number, and the same number of sets, which can be switched freely, which is conducive to the convenient collection and sorting of the cut pieces.

High-end leather cutting machines integrate artificial intelligence, visual technology and mechanical technology. While meeting diverse cutting needs, they greatly improve the utilization rate of leather materials and the precision of finished products. Whether it is a large leather factory or a high-end custom workshop, it is an important equipment for upgrading productivity and realizing digital intelligent manufacturing.

Efficient cutting, precise damage avoidance, and intelligent accompaniment - leather cutting has entered a new era of "smart manufacturing".

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109