Balls are composed of inner bladder and outer skin. Our equipment is aimed at cutting the outer skin. Here we will introduce a PU material cutting machine for cutting basketball. There are four main materials for basketball, namely cattle skin and PU. Synthetic leather, PVC synthetic leather, rubber, basketball sticks of different materials and applicable venues are different.

The cattle skin basketball emphasizes the feel of the ball, the skin is astringent but not sticky when exposed to sweat, the bounce is soft and moderate, and it is very easy to control. However, it is expensive and difficult to maintain. It is only used for indoor wooden floors and is usually used in professional games. The NBA professional league in the United States uses such basketballs.

PU synthetic leather is the most commonly used material. 80% of the balls that we play every day are made of PU leather. The advantages are that it is waterproof, wear-resistant, easy to use indoors and outdoors, and has high viscosity and good hand feel. The materials are subdivided: general PU and hygroscopic PU. Generally, PU is the most basic PU material; hygroscopic PU is sticky and flexible, but not very wear-resistant.

Although PVC synthetic leather is slightly inferior to PU synthetic leather in terms of hand feel and low temperature resistance, its waterproof, wear-resistant, mildew-resistant, and saline-alkali resistance are better than PU synthetic leather, and it has a price advantage and is economical. The skin material of the popular indoor and outdoor basketball.

Rubber is divided into ordinary rubber and foamed rubber. The former is hard and cheap, while the latter is softer and better. If it is a multi-player game, it is not recommended to use ordinary rubber basketballs even on concrete floors, because the price is not much different than that of foamed rubber or a little PU, but the risk of injury is increased.

Not just basketballs, most of the balls in the sports industry are made of PU materials, such as football, volleyball, rugby, etc. Now many factories are still using traditional manual cutting, but the emergence of COVID-19 in recent years has led to labor costs. It is getting higher and higher, and many companies have almost no profit to earn. Let me introduce you to CNC cutting PK manual cutting.

CNC cutting:

1. The cutting accuracy of the equipment is guaranteed to be ±0.1mm.

2. The utilization rate of the equipment cutting machine is more than 85%.

3. Special-shaped cutting can be realized, the edge is smooth, smooth without burrs, and no secondary processing is required.

4. The cutting cost of the equipment is 11 kWh/hour

Manual cutting:

1. The accuracy of manual cutting is ±0.4mm.

2. The utilization rate of manual cutting is more than 70%.

3. Manual cutting has low precision, slow cutting speed and high rejection rate.

4. According to the data, the daily labor cost is approximately 300-350 RMB/day. ($45-50/day)

After reading this, I believe that many manufacturers have a clear understanding of manual cutting and CNC cutting. Let's watch a video to understand how our PU material cutting machine works.

After watching the video, do you have a deeper understanding of our PU material cutting machine? Of course, there are still many people who have questions, such as price, after-sales, quality and other aspects. Read on to find out more!

In terms of price:

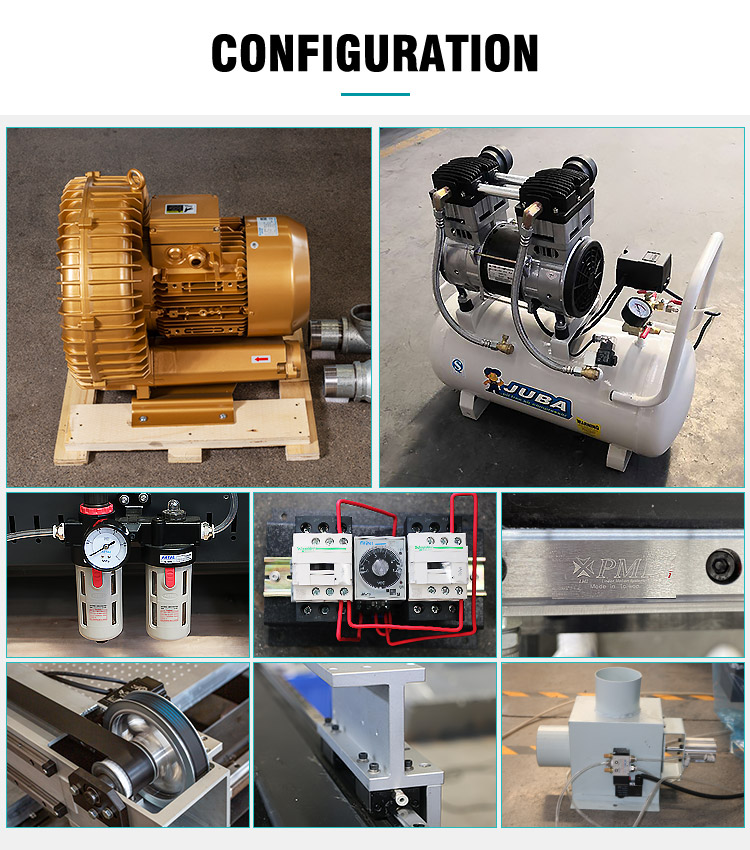

Regarding the price, it is calculated according to the model that each manufacturer decides to buy and the type of cutter head needed. For the insured price of the specific product, please contact our professionals, and they will give you a reasonable purchase price according to the machine you need. . Some people will say that the price of our machines is high. It is undeniable that there are indeed many machines on the market that are similar in form to our machines, but the prices are very different. All the accessories of our machines are imported, which is more efficient than the accessories of ordinary brands. And the quality is several times higher, so do you still think our machines are expensive?

After-sale service:

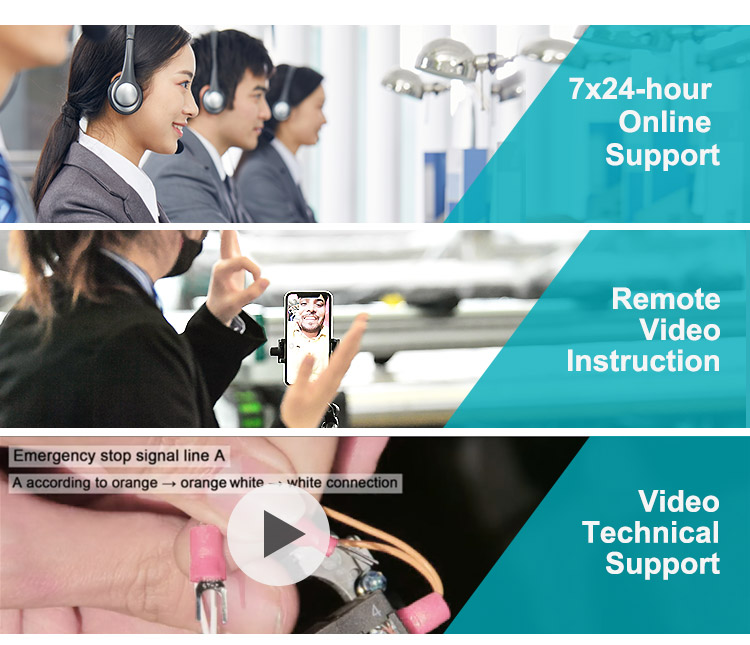

1. The AOL after-sales service team has more than 20 engineers.

2. At least 3 engineers serve an agent/customer, all of them can speak English.

3. We support complete user manual, use video and photos.

4. We support remote assistance to help you install and use the software.

5. We support 24*7 online guidance and services.

6. Our machines are guaranteed for 3 years, except for felts, knives and blades, during this period, if there is any problem, we will replace them with new ones for free by DHL, and for knives, we will repair them for free within one year.

7. We promise to send out replacement parts within 24 hours.

8. We will set up a service group for you, including AOL sales staff, AOL engineers, AOL sales managers, AOL sales directors and you (or your staff), if you have any questions, we will reply within 1 minute.

9. Free upgrade of AOL software for life.

In terms of quality:

Here is a passage to share with you: you are worried about quality, we are more worried than you, because without quality, there will be no market and no repeat customers; you are worried about integrity, we are more worried than you, because without integrity, there will be no future and no new customers will be willing to cooperate with you. We cooperate, what you worry about is what we worry about, so please rest assured, we are very reliable!

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-531-88620680

WhatsApp/We Chat: +8618560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcutcnc.com/

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109