The contemporary composite mechanical technology and processing technology with the continuous improvement of CNC automation technology are gradually forming and stabilizing. One cutting equipment can complete various types of cutting work and meet various production requirements. This production method greatly improves production efficiency and promotes the transformation of cutting methods. It seems that the development of CNC leather cutting machines should indeed develop in a composite direction, simplifying the cutting process and reducing the additional cost caused by it.

The modern machining manufacturing industry has continuously improved the requirements for the cutting quality and cutting accuracy of flexible materials, and the functional requirements of CNC leather cutting machines are also constantly improving. CNC leather cutting machines have the characteristics of fast cutting speed, precision and good cutting quality, but these characteristics must be continuously developed and expanded to meet the market demand.

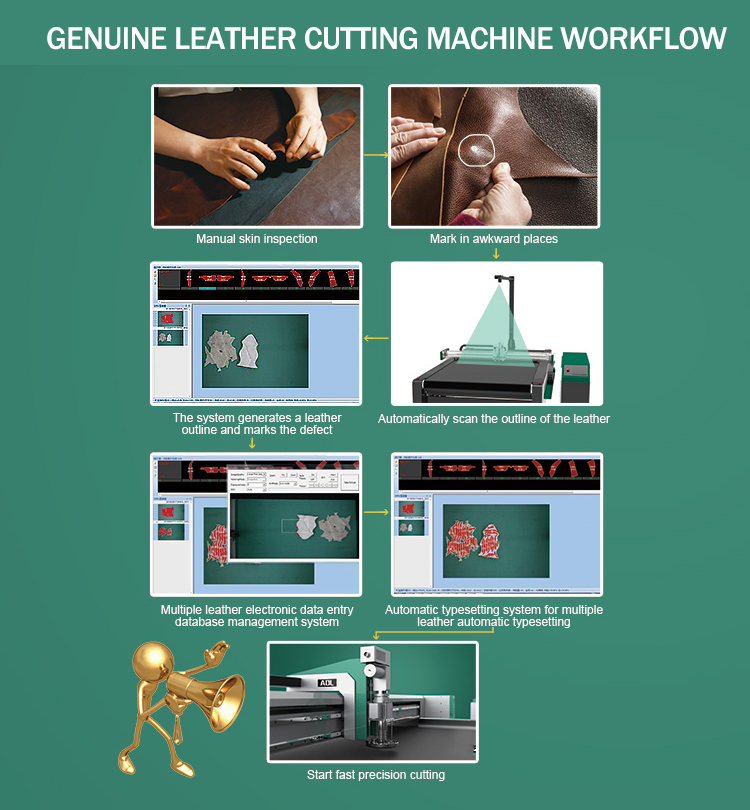

In addition, the comprehensive and intelligent development of CNC leather cutting machines is also a major development trend. Manual cutting is far less accurate than CNC cutting, and the same is true for work efficiency. Through the computer control of the CNC leather cutting machine, the working mode of the CNC leather cutting machine is transformed to an intelligent one, which is also one of the major changes of the CNC leather cutting machine.

Comparing the functional characteristics of several CNC leather cutting machines commonly used at present, the functions of CNC leather cutting machines are relatively complete. The application of graphic cutting code automatic conversion software, unique advantages of cutting leather and low investment cost, CNC leather cutting machine has come out on top in the current cutting industry.

Now the development momentum of the fine processing industry is gradually improving, and the requirements for high precision machinery are becoming more stringent. In the development direction of CNC leather cutting machine, the content of technical research accounts for a considerable proportion. The machining accuracy has gradually increased from the silk level to the micron level. Under the premise of catering to the needs of the times, products and technologies will be gradually recognized and promoted, so the comprehensive intelligence of CNC leather cutting technology is also an important aspect of its development.

Computer networking and exchanges and cooperation between enterprises are necessary ways to promote the rapid development of CNC technology. Enterprises should maintain normal communication and exchanges, analyze the market situation, and use this as a basis to upgrade and transform CNC technology. Computer networking is more conducive to the exchange of technology and promotes the technological reform of CNC cutting machines.

Cropping Video of CNC Leather Cutting Machine:

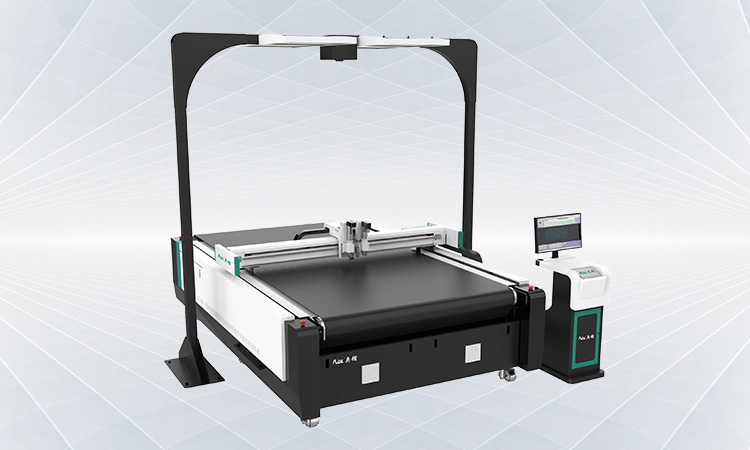

The CNC leather cutting machine is suitable for cutting any flexible material, with high cutting precision and no thermal deformation. It is a relatively environmentally friendly cutting method. CNC leather cutting machine will be the development direction of CNC cutting machine.

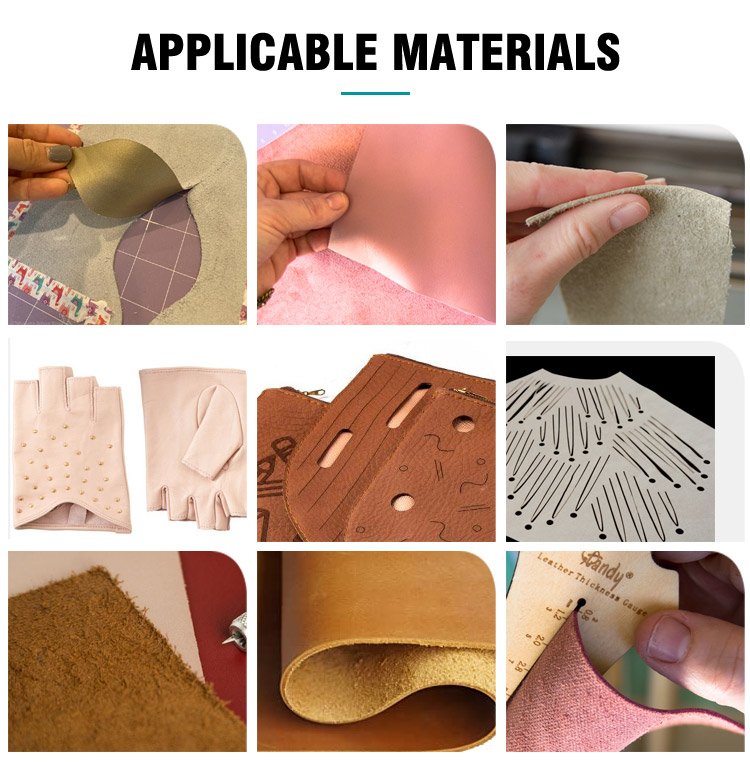

CNC leather cutting machine system, digital cutting expert, perfect combination of craftsmanship and technology. It can realize fast typesetting, efficient cutting, time saving, labor saving and material saving. Widely used, it can be used for cutting leather, PU leather, synthetic leather and other flexible materials. It is suitable for sample making and small batch production, and tailor-made revolutionary cutting solutions for shoemaking, luggage and handbags, car seats, aviation seats, furniture, clothing and other enterprises.

Using computer control, the cutting accuracy can be accurate to 0.1mm, which is more accurate and ensures product quality. The material usage rate can be increased by more than 5% on average, saving considerable material costs. The cutting speed is also 3-5 times that of manual cutting.

Seven product advantages of CNC leather cutting machine:

1. Adopting the vibrating knife cutting technology, no need to make a knife mold, it is the first to enter the era of digital knifeless mold processing.

2. Multi-functional cutting head design, cutting, punching, scribing, to achieve one-stop operation.

3. It can complete the cutting of templates that are difficult, complicated in style and cannot be realized by knife molds.

4. Powerful nesting and material counting system, automatic nesting and accurate material counting, realize digital zero inventory strategy.

5. Effectively identify leather defects, improve yield, reduce losses, and improve the effective utilization of materials.

6. Accurate computer simulation and programmed operation to avoid hidden waste, thereby improving the utilization rate of materials.

7. CNC leather cutting machine saves the time of developing and punching the board, quickly ejects the board, quickly changes the board, and quickly seizes the market opportunity.

If you want to know more about the leather cutting machine, please click to contact us, and the professionals will give you a detailed answer within 24 hours!

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcutcnc.com/

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109