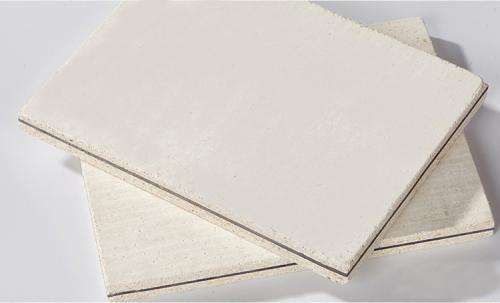

Sound insulation materials refer to a class of materials, components or structures that can block sound transmission or reduce transmitted sound energy, and are characterized by heavier mass and higher density, such as steel plates, lead plates, concrete walls, brick walls, etc. It is usually used in office or KTV. Sound waves cannot penetrate deep into the material to vibrate and rub, so the sound insulation coefficient is small. Cutting this type of material requires the use of a professional acoustic panels grooving cutting machine.

The acoustic panels grooving cutting machine can manufacture various specifications and special-shaped specifications through deep processing methods such as slitting, gluing, cutting, and molding to meet the needs of manufacturers or other supporting enterprises in the hall decoration design, home appliance quality inspection, instrument testing, automobile molding and other industries. , According to the needs of users to develop different specifications and models of sound insulation materials, sound insulation materials have the characteristics of compactness, heavy weight, strong damping, high elasticity, water resistance, good weather resistance, oil resistance, and good flame retardancy.

The advantages of sound insulation cotton are obvious, and it is very easy to process in the decoration process. At the same time, the sound insulation cotton is also moisture-proof and waterproof, and its air permeability is better than other materials. However, the sound-absorbing cotton also has its shortcomings.

Application fields of sound insulation board materials:

TV station, cinema, opera house, concert hall, conference center, gymnasium, audio room, home, shopping mall, hotel, karaoke, lounge, restaurant, car sound insulation, conference room, multi-function hall, home theater, bar, disco, Offices, industrial pipelines, villas, Internet cafes, home bedrooms, private clubs, subways and other places.

How the acoustic panels material produces the sound insulation effect:

Fiber porous sound insulation materials, such as polyester fiber cotton sound insulation cotton, centrifugal glass wool, rock wool, mineral wool, plant fiber spraying, etc. The sound insulation mechanism is that there are a large number of tiny connected pores inside the material, and sound waves can penetrate into the material along these pores. , and the friction with the material converts the sound energy into heat energy. The sound insulation characteristics of porous sound insulation materials are that the sound insulation coefficient gradually increases with the increase of frequency, which means that the low frequency absorption is not as good as the high frequency absorption. The necessary conditions for sound insulation of porous materials are: the material has a large number of voids, the voids are interconnected, and the pores penetrate deep into the material.

Commonly used functional cutter heads for cutting Acoustic panels grooving:

Vibrating knife cutting head, creasing line wheel, V-shaped cutting head and high-speed milling cutter head. The sound insulation cotton cutting machine can cut honeycomb cardboard, acrylic board, sound insulation cotton, plastic corrugated board, gray board paper, white cardboard, film, composite material, leather, cloth, rubber board, pearl cotton, aluminum plastic with a thickness of less than 30 or 60mm. Board and foam KT board and other materials. The V-shaped cutting system can cut V-shaped grooves with 5 different angles, such as 45°, 30°, 22.5°, 15°, 0°.

Why choose our Acoustic panels grooving cutting machine?

AOL has been committed to the production and optimization of CNC cutting machines. We have an independent factory, which can fully realize the design, production, sales, delivery and after-sales service processes. Our acoustic panels grooving cutting machine is fast, easy to operate, and perfectly realizes the cutting shape you want. The whole process is automated without manual intervention. It adopts high-efficiency and high-precision servo motors, which can realize intelligent cutting faster and more accurately. Perfect pre-sale and after-sale service, pre-sale plan for you according to the specific situation of your cutting material, one-to-one guidance after sale, to ensure that you can master the operation method as soon as possible.

If you have anything else you want to know, please contact us, we will have professional staff to answer all your questions!

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109