Textiles must know how to cut

What is the textile industry

A textile[1] is a flexible material made by creating an interlocking network of yarns or threads, which are produced by spinning raw fibres (from either natural or synthetic sources) into long and twisted lengths.Textiles are then formed by weaving, knitting, crocheting, knotting, tatting, felting, bonding, or braiding these yarns together.

The related words "fabric" and "cloth" and "material" are often used in textile assembly trades (such as tailoring and dressmaking) as synonyms for textile. However, there are subtle differences in these terms in specialized usage. A textile is any material made of the interlacing fibres, including carpeting and geotextiles, which may not necessarily be used in the production of further goods, such as clothing and upholstery. A fabric is a material made through weaving, knitting, spreading, felting, stitching, crocheting or bonding that may be used in the production of further products, such as clothing and upholstery, thus requiring a further step of the production. Cloth may also be used synonymously with fabric, but often specifically refers to a piece of fabric that has been processed or cut.

Textile use

Textiles have an assortment of uses, the most common of which are for clothing and for containers such as bags and baskets. In the household, textiles are used in carpeting, upholstered furnishings, window shades, towels, coverings for tables, beds, and other flat surfaces, and in art. In the workplace, textiles can be used in industrial and scientific processes such as filtering. Miscellaneous uses include flags, backpacks, tents, nets, handkerchiefs, cleaning rags, transportation devices such as balloons, kites, sails, and parachutes; textiles are also used to provide strengthening in composite materials such as fibreglass and industrial geotextiles. Textiles are used in many traditional crafts such as sewing, quilting and embroidery.

Textiles produced for industrial purposes, and designed and chosen for technical characteristics beyond their appearance, are commonly referred to as technical textiles. Technical textiles include textile structures for automotive applications, medical textiles (such as implants), geotextiles (reinforcement of embankments), agrotextiles (textiles for crop protection), protective clothing (such as clothing resistant to heat and radiation for fire fighter clothing, against molten metals for welders, stab protection, and bullet proof vests).

Due to the often highly technical and legal requirements of these products, these textiles are typically tested in order to ensure they meet stringent performance requirements. Other forms of technical textiles may be produced to experiment with their scientific qualities and to explore the possible benefits they may have in the future. Threads coated with zinc oxide nanowires, when woven into fabric, have been shown capable of "self-powering nanosystems", using vibrations created by everyday actions like wind or body movements to generate energy.

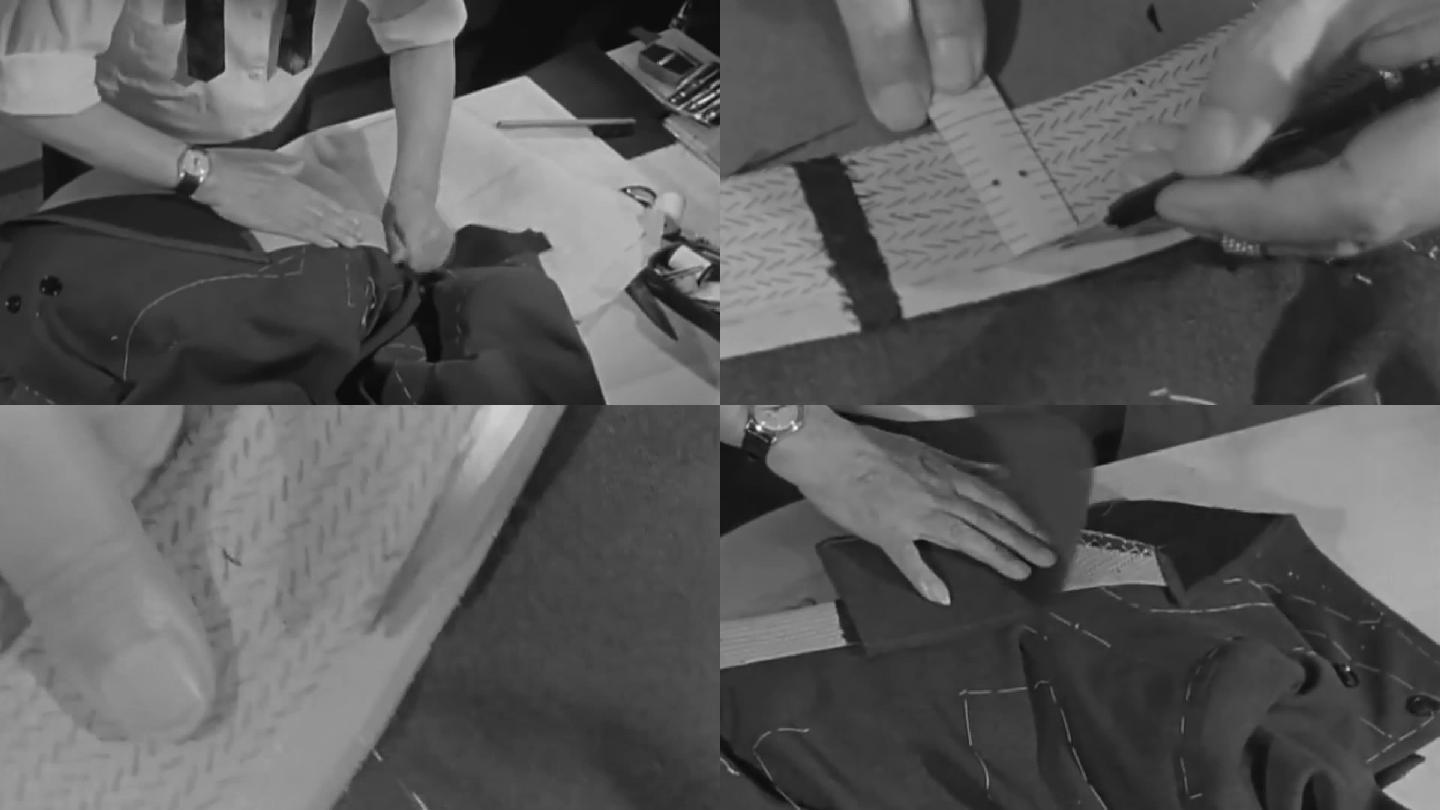

Cutting method

1. Manual cutting

At the beginning of textile manufacturing, due to technical limitations, blades were used for cutting. At that time, manual cutting was a common method. But now that technology has developed and manual costs have risen rapidly, manual tailoring has become synonymous with advanced customization.

Process

1. Measure the cutting length

2. Mark the cutting point, line and surface

3. Use a knife to cut

Which Tools Are Best?

Serrated shears cut knits and slippery fabrics best.

Use sharp shears to get the best cuts.

Use all-purpose scissors for everything other than fabric, like pattern paper or packages.

A rotary cutter will aid in assisting with lots of straight cuts. A rotary mat and a ruler will make this cutting process easier.

Use a vinyl tablecloth to protect tabletop surfaces and help with slippage.

Pay Attention to Grainlines

Distinguish warp and weft thread before cutting (aka grainlines). Find the grainline and cut it as needed by folding the fabric in half where the two selvages meet to allow the fabric to hang correctly and make symmetrical cuts. Garments are usually cut lengthwise because they are stronger this way and the garment will fall properly when cut unless the pattern states otherwise.

2. Laser cutting

With the development of technology, the invention of laser makes it gradually applied to the textile industry, because it brings higher efficiency and economic output. The basic principle of laser cutting is to realize the cutting of textile materials through high temperature.

3. CNC blade cutting machine

The CNC blade cutting machine not only integrates the high-efficiency cutting of the laser cutting machine, but also solves the problem of low accuracy of manual cutting.

The CNC system controls the cutting path and reduces the manual participation rate.

Advantage of AOL textiles cutting machine

1. AOLCUT software one-key import function, multi-format compatible file content, one-key reading, no need to change the format.

2. AOL cut system is equipped with intelligent optimized cutting layout, saving 10% of material cost.

3. Use Taiwan linear guide drive system, cutting accuracy ±0.1mm

4. Select Japanese Panasonic servo system to increase production efficiency by more than five times

5. AOL's unique tool exchange system, cutting, punching and marking are automatically completed

6. Automatic pulling and receiving, saving time and effort

7. Save more than 500,000 labor and raw materials every year, which greatly improves product competitiveness

AOL CNC Equipment Co., Ltd. is a high-tech enterprise specializing in the development, manufacture, sales and after-sales service of cutting and laser cutting machines for flexible materials. It mainly includes CNC intelligent blade cutting machines, engraving machines and other types of cutting machines, which can meet the cutting processing of acrylic engraving and flexible materials of different materials, and is widely used in advertising packaging, Composite materials, carpet industry, clothing textile, automotive interior, leather industry. In addition, AOL also has an independent CNC cutting machine brand aoyoo.

AOL CNC Equipment Co., Ltd. is a AAA credit enterprise in China's high-tech industry. The product quality has passed multiple tests and the after-sales system is perfect. It has provided reliable CNC cutting machines for more than 8000 users around the world and professional cutting line solutions for many users.

For more information about product performance, please click jump product

AOL Media

E-mail:info@aolcnc.com

phone:+86-0531-88620680

WhatsApp /wechat:0086-18560162709

Youtube:https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website:https://www.aolcutcnc.com/

Facebook:https://www.facebook.com/aolcuttingmachine

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109