Nowadays, the usage rate of carpets in people's lives is getting higher and higher. Placing carpets around the home can not only beautify the living environment, but also play a role in sound absorption, noise reduction, anti-skid and warmth. Some carpets will have a very comfortable feeling when you step on them, improving the comfort of the room.

But there are many kinds of carpet materials. Today, I will share with you what kind of environment the carpets of different materials are suitable for. For manufacturers, which cutting equipment should be used for carpet cutting?

Pure wool carpets: Generally speaking, pure wool carpets are woven from wool or other animal hair, with long fibers, high tensile force, good elasticity, and their own luster, and the woven wool fibers are thicker. Generally used in high-end guest rooms, stages, living rooms and other places, it is a relatively high-end decoration material. This kind of carpet is generally mainly produced by hand, with high cost and poor utilization rate.

Leather carpet: This kind of carpet is a carpet made of animal skins through simple cutting and sewing operations, and the cost is also very high. Some of them use a complete animal skin as a carpet, which is mainly produced by hand.

Blended carpets: Compared with pure wool, blended materials are woven from wool fibers mixed with synthetic fibers. Compared with pure wool, it has better wear resistance, lower price and high decoration performance. It is the material with the highest utilization rate.

Chemical fiber carpet: It is a kind of synthetic fiber carpet, such as acrylic, polypropylene, acrylic, nylon, etc., which has good wear resistance and elasticity, but lacks comfort and aesthetics. Most of them are used for basic building decoration or outdoor decoration.

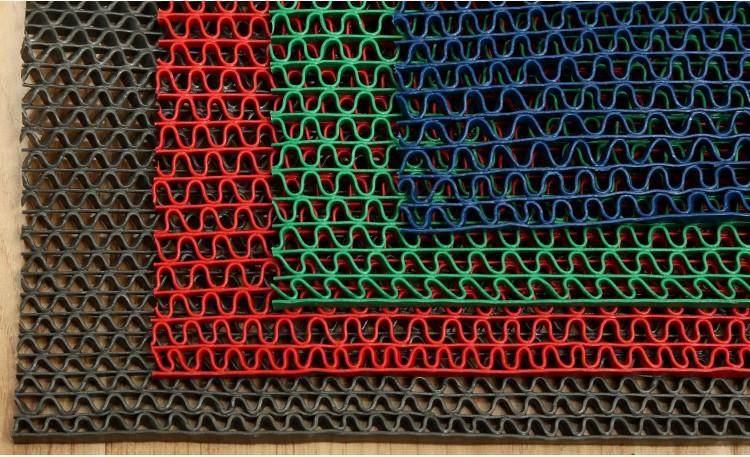

Plastic carpet: Plastic carpet is produced by mixing and smelting polyethylene resin, plasticizer, etc. It is colorful, comfortable and durable, and also has waterproof function, so it is generally used in hotels, shopping malls, stages or in bathrooms. . Each material has its own advantages and disadvantages. When choosing a carpet material, it can be comprehensively considered according to the usage scene and your own needs.

With a preliminary understanding of the material of the carpet, how to choose the appropriate cutting and cutting equipment when cutting the carpet?

Here, the hand-produced carpets are first removed, because the hand-processed carpets have been produced according to the required shape and size during the processing process, and there is no post-processing and cutting process, so the carpet cutting machine is mainly for mechanically produced carpet materials. , such as synthetic fibers, blended carpets, pvc carpets, composite cotton carpets, plush carpets, printed carpets, rubber carpets, etc.

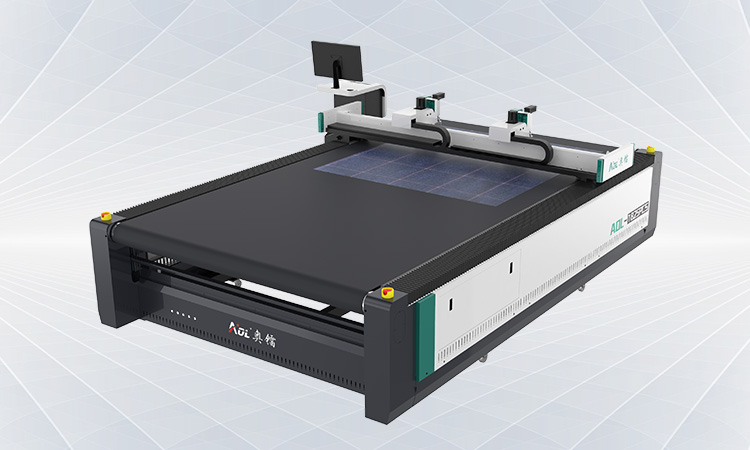

AOL carpet cutting machine can replace the cutter head, use vibrating cutter, circular cutter, pneumatic cutter and other cutters to meet the special-shaped cutting and cutting needs of various carpet materials.

The data layout can be directly imported into the intelligent software to realize the automatic layout of the layout, improve the production efficiency and reduce the waste of materials. An industrial camera can also be installed to identify the pattern of the material to be cut, automatically identify the printing pattern on the material, intelligently generate the cutting path, and cut quickly, with high precision and high speed. Suitable for carpet customization, mass production, splicing, etc.

The above has introduced the types of carpets commonly seen in life in detail, and also introduced how to choose a suitable cutting machine. If you have any questions about the price of the machine or want to know more about the machine, please contact us, professional The staff will answer you within 24 hours!

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109