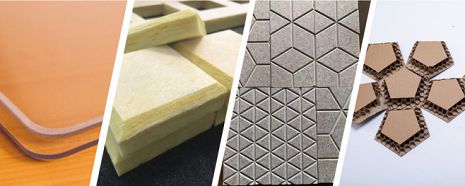

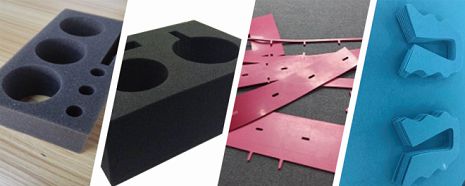

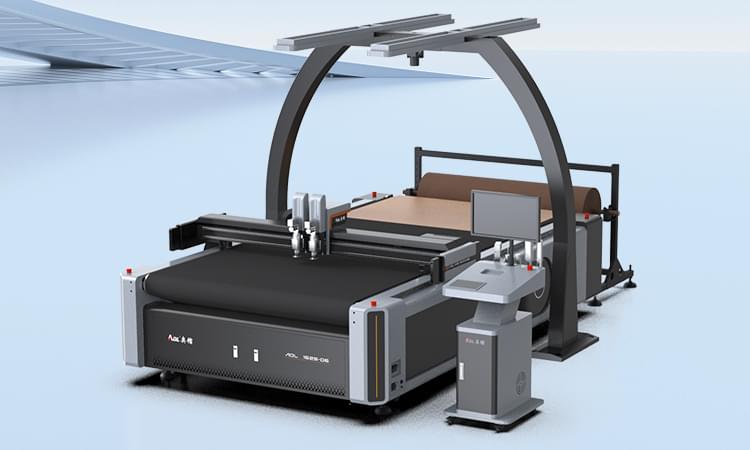

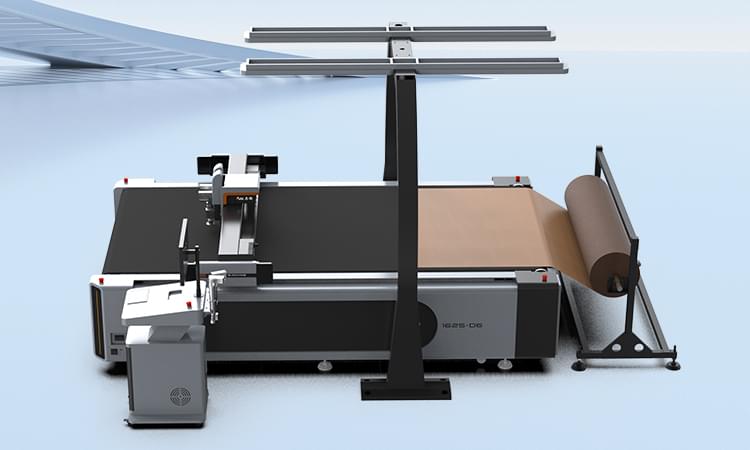

AOL digital automatic leather luggage shoes cutting machine can cut multi-layer PU leather, which can solve the problem of small batch customization and multi-style special-shaped cutting in factories. Can realize multi-layer cutting, cutting of various PU materials, such as upper material, natural leather, synthetic leather, saddle leather, shoe leather, sole material, face leather, leather bag, leather gloves, leather shoes, car interior, sole cutting, seat Covers, printed leather, PU leather, mesh, wool slippers, sponge shoes, golf bags, casual shoes and other materials. In addition to cutting leather materials, it can also cut various non-metal flexible materials such as advertising packaging industry, garment textile industry, carpet industry, automobile interior industry, composite material industry and so on.

How does the AOL digital automatic leather luggage shoes cutting machine work?

AOL digital automatic leather luggage shoes cutting machine related parameters:

| Material | AOL digital cutter efficiency | Manual cutting efficiency | Instead of manual quantity |

| Leather clothing | 250mm/s | 80-100mm/s | 3 pepole |

| Pu skin | 500mm/s | 150mm/s | 3 pepole |

| Imitation leather | 500mm/s | 150mm/s | 3 pepole |

| Belt | 300mm/s | 25mm/s | 4 pepole |

| Genuine Leather | 300-400mm/s | 25-50mm/s | 3-4 pepole |

| Leather | 300-400mm/s | 25-50mm/s | 3-4 pepole |

| Cow leather | 300-400mm/s | 25-50mm/s | 4 pepole |

| Horsehide | 300-400mm/s | 25-50mm/s | 3-4 pepole |

| Sheepskin | 300-400mm/s | 25-50mm/s | 3-4 pepole |

| Sheep leather | 300-400mm/s | 25-50mm/s | 3 pepole |

| FUR GARMENT | 300-400mm/s | 25-50mm/s | 3-4 pepole |

| Patent leather | 300-400mm/s | 25-50mm/s | 5 people |

| Cowhide | 100mm/s | 10mm/s | 3 people |

| Artificial leather | 150mm/s | 15mm/s | 4 pepole |

| Full leather | 300-400mm/s | 25-50mm/s | 3-4 people |

| Crocodile skin | 300-400mm/s | 25-50mm/s | 4 pepole |

| Real leather | 300-400mm/s | 25-50mm/s | 3 pepole |

| Tire cow | 300-400mm/s | 25-50mm/s | 3 pepole |

| Turn fur | 300-400mm/s | 25-50mm/s | 2-3 people |

| Backpack | 400mm/s | 200mm/s | 2 people |

Pu package |

400mm/s | 200mm/s | 2 people |

| Leather bag | 300-400mm/s | 100-150mm/s | 4 pepole |

| Canvas bag | 150mm/s | 50mm/s | 4 pepole |

| Travel bag | 150mm/s | 50mm/s | 4 pepole |

| Fur bag | 500mm/s | 200-300mm/s | 4 pepole |

| Pu shoes | 300mm/s | 100mm/s | 5 pepole |

| Car luggage | 150mm/s | 50mm/s | 4 pepole |

| Travel luggage | 150mm/s | 50mm/s | 4 pepole |

| Canvas bag | 150mm/s | 50mm/s | 4 pepole |

| Cloth shoes | 1800-2000mm/s | 800-1000mm/s | 3-4 pepole |

| Shoes | 2000mm/s | 1000mm/s | 5-6 people |

| Leather shoes | 300-400mm/s | 100-150mm/s | 3-4 pepole |

| Boots | 2000mm/s | 1000mm/s | 3-4 pepole |

| Canvas shoes | 1800-2000mm/s | 800-1000mm/s | 3-4 pepole |

| Casual shoes | 1500-1800mm/s | 600-800mm/s | 3-4 pepole |

| High heels | 600-800mm/s | 200-300mm/s | 3-4 pepole |

| High heel shoe |

500-600mm/s | 200-300mm/s | 3-4 pepole |

| Heightening shoes | 600-800mm/s | 200-300mm/s | 3-4 pepole |

| Snow boots | 150mm/s | 50mm/s | 3-4 pepole |

| Wallet | 600mm/s | 200mm/s | 3-4 pepole |

| Handbag | 400mm/s | 200mm/s | 2 pepole |

| The above data is for reference only, the actual operation, affected by the thickness, hardness, flexibility, etc. of the material, the data will be biased. | |||

Technical parameters / model |

AOL-1625 |

AOL-1825 |

Effective working area |

1600x2500mm |

1800x2500mm |

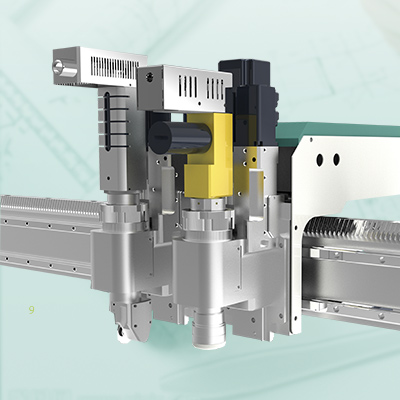

Multi-function tool |

Oscillating knife, round knife, pneumatic knife, drag knife, half cutting knife, press wheel, V-CUT Knife Tool, milling cutter, drawing marker pen, ink cartridge inkjet, cursor positioning, camera positioning edge patrol |

|

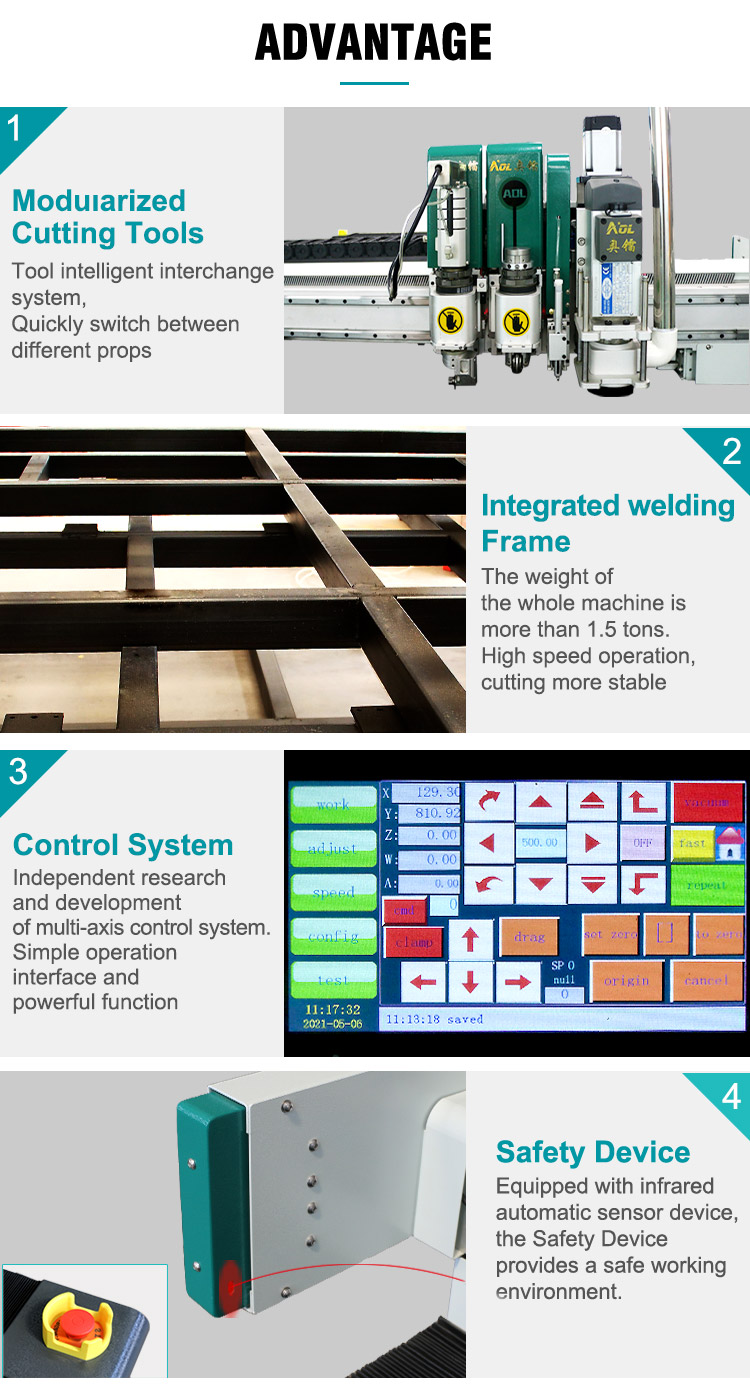

| safety devices | Four corners emergency stop, anti-collision safety device using infrared induction, safe and reliable |

|

| Cutting tool configuration | Pneumatic knife、punching tool | |

Cutting speed |

50-100mm/s |

|

Cutting thickness |

≤15mm Other thicknesses can be customized according to the material |

|

Applicable materials |

Genuine leather, PU leather, PVC leather and other leather or matching leather materials |

|

Material fixing method |

Vacuum partition adsorption |

|

Transmission port |

Network port |

|

Transmission system |

The X\Y axis is divided into two kinds of rack or belt |

|

rated power |

11kw |

|

Rated voltage |

380V±10%/220V±10% Optional |

|

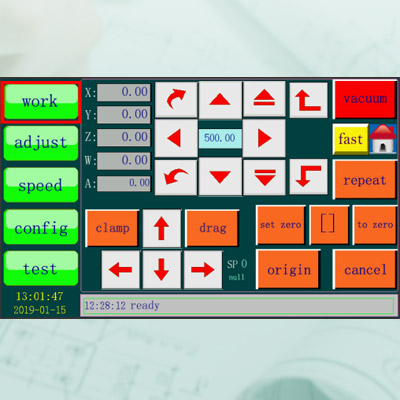

Control System |

Chinese and English LCD touch screen |

|

Operating environment |

Operating environment Temperature 0-40°C Humidity 20%-80%RH |

|

Support file format |

AI、PLT、DXF、PDF、 PCE、XML |

|

| Overall size | 3600x2400x1200mm |

3600x2600x1200mm |

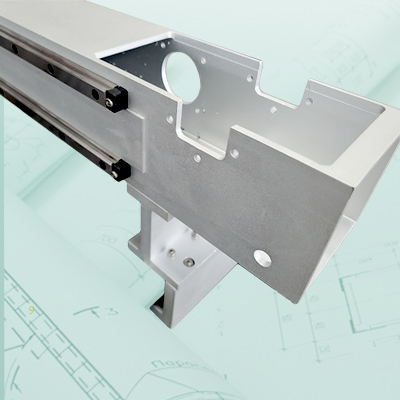

| Other configuration | import servo motor,high precision helical gear reducer,import rail,rack,sensor,low-voltage appliances,power supply, cable,42mm adsorption platform,automatic feeding,rail,energy saving fan | |

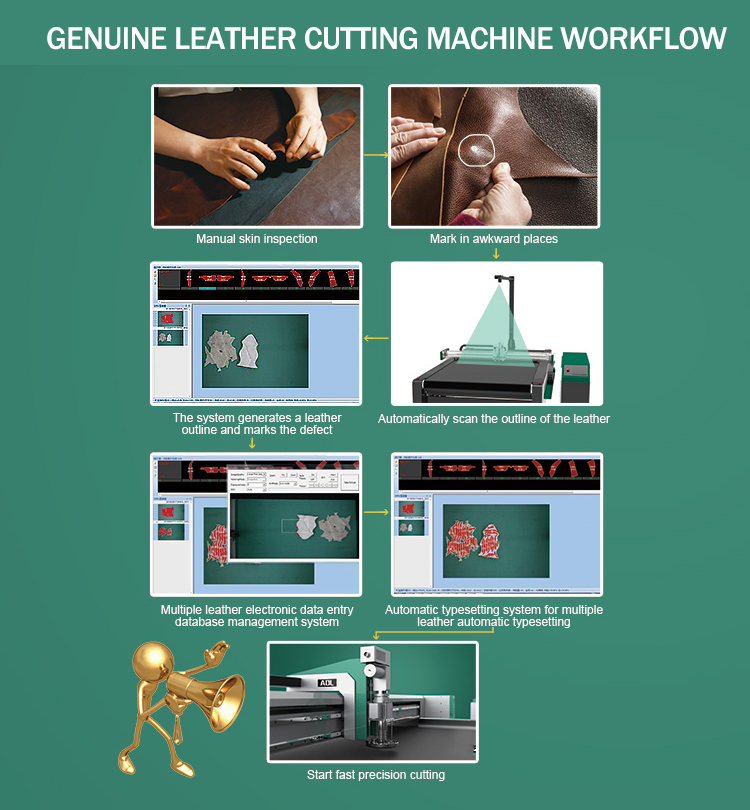

AOL Digital Automatic Leather Luggage Shoe Cutting Machine Workflow:

First of all, it is necessary to carry out manual leather inspection, find out the defects and mark them with a pen, put the material on the felt for photo identification, and the software will take pictures to identify the contours, holes and defects. The equipment has a leather contour identification system, which can quickly and accurately identify cutting irregularities. Defects in the material, so as to achieve efficient cutting and high utilization of leather. Computers have automatic typesetting to maximize the use of materials while avoiding defects. After internal data processing, it is transmitted to the machine control card. The control card sends the command pulse signal to the servo driver, and the driver drives the servo motor to move. The movement of the machine is realized, and at the same time, a signal is sent to the tool to cut the raw material.

The processing advantages of the machine:

1. Simultaneous cutting with two heads is equivalent to twice the efficiency of a single head, saving a lot of cutting time.

2. High-definition CCD camera, realize automatic positioning and nest cutting of various materials, and cut special-shaped patterns quickly and accurately.

3. Using high-power motor and oscillating knife tools, small batch orders can be quickly cut to improve work efficiency

4. Vacuum adsorption function, super suction, ensure material fixation, three adsorption modes, greatly reduce power consumption

AOL digital automatic leather luggage and shoe cutting machine does not require abrasives, cutting without deformation, cutting edge without yellowing or scorching, smokeless and odorless, safe and environmentally friendly, and easy to maintain.

8 reasons to choose us:

1. There is an independent factory, which can realize the integrated process and support customization.

2. There is a professional after-sales team, at least three engineers serve a customer or agent, and can explain the whole process in English.

3. All imported machine parts are used to ensure that the machine can run stably and for a long time.

4. Three-year warranty service (except wearing parts).

5. The professional R&D team can provide supporting solutions until the customer is satisfied.

6. Support 24*7 online guidance and services.

7. AOL software is free to upgrade for life.

8. We will set up a service group for you, including AOL sales staff, AOL engineers, AOL sales managers, AOL sales directors and you (or your staff), if you have any questions, we will reply within 1 minute.

Company Info:

AOL is a famous CNC equipment factory. AOL mainly produce CNC Knife Cutting Machine, Cutting Plotter, CNC Cutting Table and so on. We, as a high-tech enterprise, engaged in research, manufacture and sell the CNC cutting machine and relevant products.

AOL has gained CE certificate, FDA and ISO certificate. Company successfully produce AOL series products of more than 50 sorts, which enjoy good reputation and support. Excellent quality and fast service makes our products spread all over the world as Europe, America, Middle east and South of Asia.

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.

Cutting materials: kt board , foam board, honeycomb board, car mat, seat cover, corrugated, cardboard, kt board, gray board, composite materials, leather, corrugated box.

Cutting materials: Packing box, folding card, corrugated Board, carton,etc.

Cutting material: soft board , kt board , corrugated board, packing box, slotting of corrugated boxes, medium-density material v cuts, carton packaging, hard cardboard, gift boxes,etc.

Cutting materials: sticker, car sticker, reflective materials, self-adhesive vinyl, label, vinyl, engineering reflective film, double-layer adhesives, etc.

Cutting materials: asbestos board, asbestos free board, PTFE, rubber board , fluorine rubber board, silica gel board, graphite board, graphite composite board, etc.

Cutting materials: acrylic MDF board, pvc board, display stand, etc.

Cutting materials: backlit film, sticker, pp paper , folding card, flexible material less than 3mm thickness, advertising materials KT board, flexible plastics, mobile phone film, etc.

Cutting materials: textiles, canvas, leather, fabric, carbon fabric, glass fabric, carpet, blanket, fur, woven fabric, composite double, multi-layer material, flexible plastic, etc.

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109