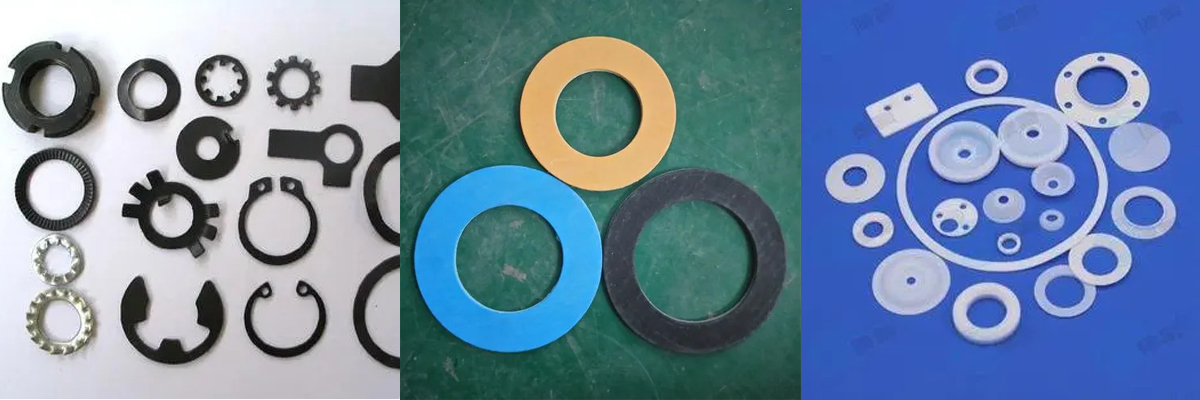

A gasket cutting machine is a specialized piece of equipment designed to precisely cut gaskets from various materials such as rubber, cork, graphite, PTFE, and fiber. These machines are widely used in industries like automotive, aerospace, oil and gas, and manufacturing, where gaskets play a crucial role in sealing and preventing leaks between mating surfaces.

Our Software offers a neat and quick solution for cutting grooves in rubber materials. In contrast to milling v-grooves, there is no swarf and the process speed is increased many times over.

Gasket is a kind of sealing spare parts used in machinery, equipment and pipelines as long as there is fluid. It uses internal and external materials to play a sealing role.

It is made of metal or non-metal plate material by cutting, punching or cutting and other processes. It is used for sealing connection between pipes and sealing connection between parts of machinery and equipment.

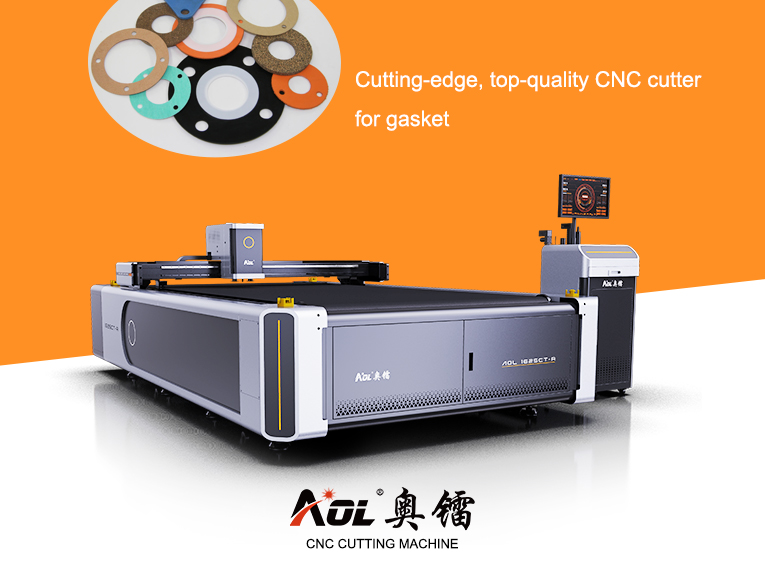

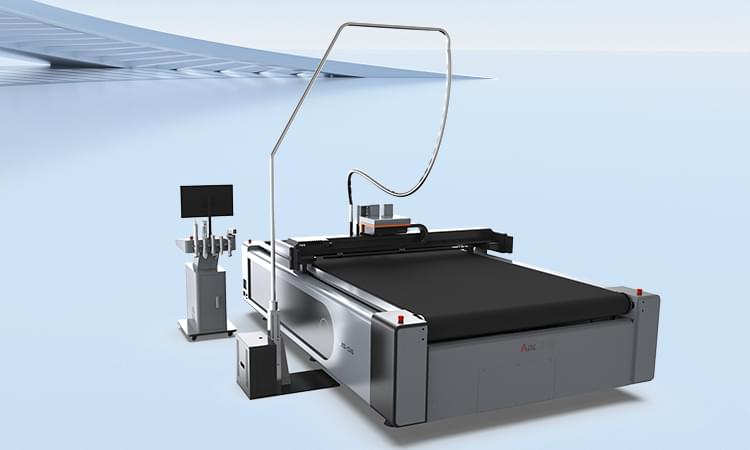

A CNC Gasket Cutting Machine is a computer-controlled cutting device that employs specialized software and precision machinery to fabricate gaskets of various shapes and sizes. Unlike conventional methods, where gaskets are hand-cut using templates, CNC machines follow digital designs with unparalleled accuracy. These machines operate on a subtractive manufacturing principle, where a gasket material is trimmed to the required shape by removing excess material.

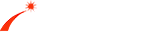

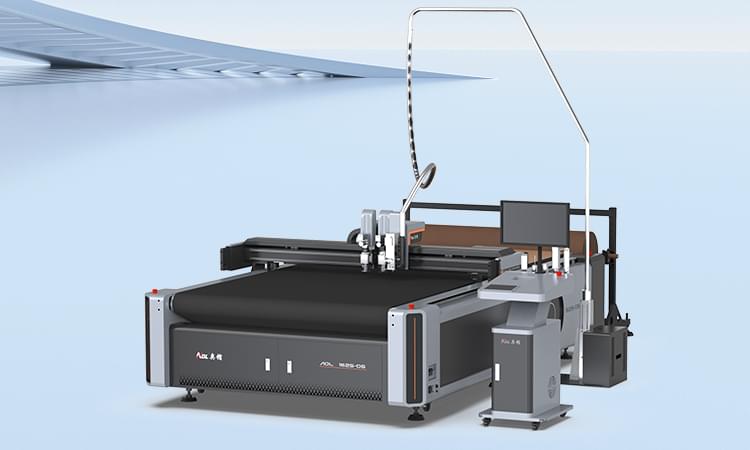

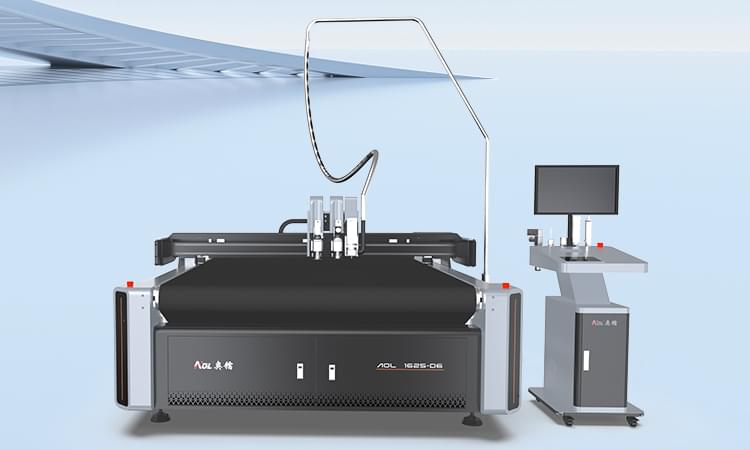

Related parameters of CNC gasket cutting machine:

| Model | AOL-1625DCS | AOL-1825DCS |

| Working area | 2500×1600mm | 2500×1800mm |

| Machine size (mm) | 3600*2400*1250 | 3600*2600*1250 |

| Rated power | 11KW | |

| Fixed mode | Vacuum adsorption, automatic feeding type table | |

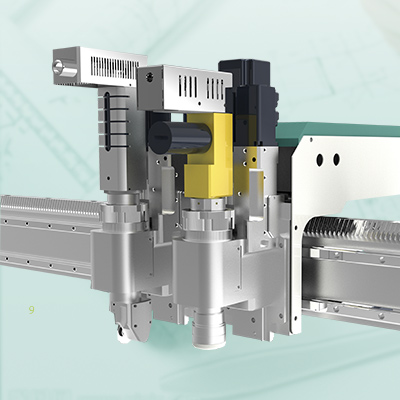

| Multifunctional head | Pneumatic knife, Milling tool, projector,vibrating knife | |

| Tool configuration | Multiple cutting knives | |

| Safety device | Using infrared sensors, responsive, safe and reliable Anti-collision system Four corner emergency stop button |

|

| translational velocity | 800-2000mm/s | |

| Cutting speed | 0-1800mm/s(according to different cutting materials) | |

| Cutting thickness | ≤50mm(according to different cutting materials) | |

| Cutting materials | Asbestos, graphite, rubber, silica gel, PTFE, expanded PTFE, pvc, cork, etc. | |

| Repeated accuracy | ±0.1mm | |

| Capacity | 2GB | |

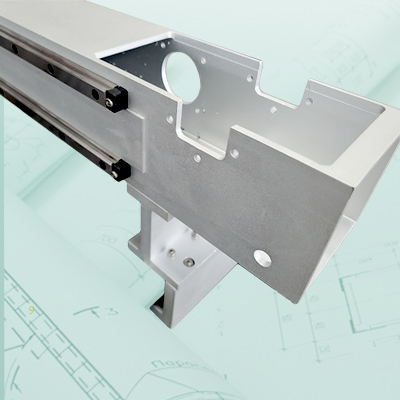

| Transmission system | Precision grinding rack drive | |

| Instruction system | AI、PLT、DXF、PDF、 PCE、XML | |

| Other configuration | import servo motor,high precision helical gear reducer,import rail,rack,sensor,low-voltage appliances,power supply, cable,42mm adsorption platform,automatic feeding,rail,energy saving fan | |

| Type of gasket | Thickness | AOL digital cutter efficiency | Manual cutting efficiency | Instead of manual quantity |

| Graphite gasket | 1.5mm | 300mm/s | 50-100mm/s | 2 pepole |

| 2mm | 300mm/s | 50-100mm/s | 2-3 people | |

| 5mm | 100mm/s | 10mm/s | 4 people | |

| Ordinary gasket | 3mm | 300mm/s | 50-100mm/s | 2-3 people |

| 5mm | 200mm/s | 50mm/s | 2-3 people | |

| Rubber gasket | 3mm | 200mm/s | 50mm/s | 3 people |

| 5mm | 100mm/s | 10mm/s | 3 pepole | |

| 10mm | 50mm/s | ≤10mm/s | 4 pepole | |

| PTFE gasket | 3mm | 150mm/s | 10-50mm/s | 3-4 pepole |

| 5mm | 100mm/s | 10mm/s | 3-4 pepole | |

| The above data is for reference only, the actual operation, affected by the thickness, hardness, flexibility, etc. of the material, the data will be biased. | ||||

The automatic sealing gasket cutting machine does not need to be punched. It only needs to import the data into the system to identify and cut the material. The automation of this step directly saves a lot of time and cost.

The super nesting software is supplemented to complete the typesetting intelligently and accurately, without manual nesting. After a lot of tests, using the CNC gasket cutting machine saves more than 10% of materials than manual labor. You can use this data to calculate how much you can save in a year.

The cutting is more accurate. The sealing gasket has high requirements in this regard. If there is an error, it will not match, which affects many aspects. In the process of cutting, the manual punch has a higher probability of deviation, and the machine passes through the software system. which can minimize the error.

The machine is intelligent and automated, the operation is very simple, the number of workers required is small, and it can work continuously for 24 hours, getting rid of the problems of high labor cost and difficult recruitment.

Applications of CNC gasket cutting:

Automobile industry:

CNC gasket cutting is widely used in the automotive industry to produce precision gaskets for engines, transmissions, and various other components. The ability to efficiently manufacture custom gaskets is critical to vehicle performance and reliability.

Electronics and Technology:

In the electronics industry, where miniaturization and precise sealing are critical, CNC gasket cutting is critical for manufacturing gaskets that protect delicate electronic components from environmental factors.

Aerospace field:

Critical applications in the aerospace industry require high performance gaskets. CNC gasket cutting ensures gaskets meet strict specifications, contributing to the safety and reliability of aerospace systems.

Industrial equipment:

CNC gasket cutting is widely used in the production of industrial machinery gaskets, ensuring optimal sealing and performance in challenging environments.

What can a gasket cutter do?

A gasket cutter can meet all your gasket form needs, from simple to complex, from prototype to mass production, and from design or CAD files.

The choice of gasket material is critical to maintaining a precise seal, depending on mechanical, chemical, thermal or acoustic constraints. There are graphite, PTFE, aramid, carbon, fiber, mica, elastomers, flexible rubber and other materials to choose from.

Major buyers work with gasket manufacturers in the following industries: food processing, chemicals, energy production, petrochemical, aviation, automotive, etc.

Benefits of using a gasket cutter:

One of the most significant advantages of using a gasket cutter is that it allows you to accurately and precisely cut gaskets of any size and shape. You can do this using the machine's digital control system, which ensures that the machine operates accurately and the cuts are precise. In addition, the machine's ability to be programmed with a wide range of shapes and sizes means that you can feed the machine an unlimited number of gaskets, reducing machine downtime and avoiding unnecessary expenses. Finally, these machines have a high cutting speed that significantly reduces the time required for gasket cutting.

How does a gasket dieless knife cutter work?

CNC Shim Dieless Knife Cutters do not require custom dies. They are built around a CNC system that includes a programmable oscillating blade cutter on a bed-style table.

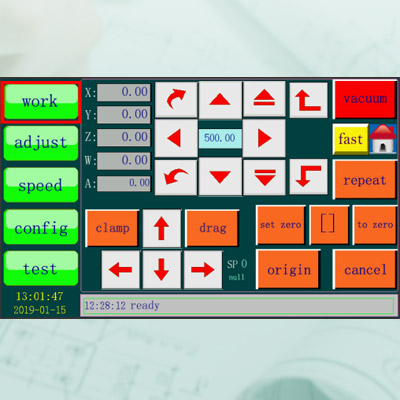

A projection system projects the design directly onto the cutting table. This enables the operator to view and improve the layout before any cuts are made.

Nesting software enables intelligent stacking within shapes, increasing yields and reducing waste.

Company Info:

AOL is a famous CNC equipment factory. AOL mainly produce CNC Knife Cutting Machine, Cutting Plotter, CNC Cutting Table and so on. We, as a high-tech enterprise, engaged in research, manufacture and sell the CNC cutting machine and relevant products.

Widely used in advertising packaging, composite materials, carpet industry, clothing textiles, automotive interiors, and leather industries. In addition, AOL also has an independent CNC cutting machine brand AOYOO.

AOL has gained CE certificate, FDA and ISO certificate. Company successfully produce AOL series products of more than 50 sorts, which enjoy good reputation and support. Excellent quality and fast service makes our products spread all over the world as Europe, America, Middle east and South of Asia.

AOL CNC Equipment Co., Ltd. is a high-tech industry in China and an AAA-level credit enterprise. The product quality has undergone multiple tests and the after-sales system is complete. It has provided reliable CNC cutting machines for more than 8,000 users worldwide. Provide professional industry cutting assembly line solutions for many users.

AOL online services

1) Three-year free warranty (except wearing parts), free inspection and maintenance of major components.

2) Provide lifetime free technology upgrade service

3) Wearable parts (e.g. blades, bench covers) are always available at cost when needed.

4) Free operation training in our factory. If there is not enough time, we will send a detailed training video.

5) 24-hour online service, providing free technical support in different languages.

6) On-site technical support can be provided when needed.

Cutting machine packaging

1. Outer packaging: standard sea export plywood box.

2. Inner packaging: stretchable film and plastic film to prevent moisture.

If you have special requirements, we can negotiate amicably; if there is anything else you want to know, please contact us.

About warranty policy

Our standard warranty period begins upon completion of delivery. We provide you with a three-year warranty and provide professional machine repair and maintenance

Update and maintenance of machine parts are sold to customers at the lowest price.

FAQ:

1.What is the cutting accuracy of a gasket cutter?

Typical accuracy is ±0.1mm, making it suitable for precision gasket manufacturing with high sealing requirements.

2.Is it difficult to operate? Does it require specialized technicians?

The user interface is simple, and most machines support direct import of CAD files, allowing ordinary workers to operate after brief training. Maintenance is also relatively easy.

3.What is the cutting speed of a gasket cutter?

Depending on the material and thickness, the speed generally ranges from 1000–1800 mm/s.

4.Is the maintenance cost of a gasket cutter high?

Routine maintenance is relatively low, primarily involving blade replacement, regular workbench cleaning, and CNC system inspection.

5.Can a gasket cutter cut a variety of complex patterns?

It can cut complex patterns and special-shaped patterns without the need for molds, and its high cutting accuracy makes it ideal for applications in the aerospace and pharmaceutical industries with tight tolerances.

6.What part sizes can a CNC gasket cutter cut?

Our standard working sizes (mm) are 1600*2500; 1800*2500; 1600*3000; and 1600*6000, among other sizes. We can also manufacture custom sizes of automatic CNC knife cutting machines to meet your requirements.

7.How much does a gasket cutting machine cost?Pricing for each project depends on the difficulty of the design, the materials used, the time required for cutting, and the cutting module used.

That being said, we offer competitive pricing, high-quality service, and fast turnaround times.

8.How long does it take to cut a gasket using a gasket cutting machine?Cutting time is affected by the complexity of the design and the thickness and density of the raw material.

AOL can produce cut parts for large orders, just as we can produce small batches or single pieces.

Our automatic CNC knife cutting machines are designed to operate 24/7 and are optimized for speed and durability.

The CNC Gasket Cutting Machine has significantly transformed the gasket manufacturing process, making it more efficient, precise, and cost-effective. Its ability to deliver consistent results and accommodate a wide range of materials and designs has made it an invaluable tool in various industries. As technology continues to evolve, we can expect even more sophisticated CNC machines, further enhancing gasket manufacturing capabilities and contributing to advancements in critical fields.

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.

Cutting materials: kt board , foam board, honeycomb board, car mat, seat cover, corrugated, cardboard, kt board, gray board, composite materials, leather, corrugated box.

Cutting materials: Packing box, folding card, corrugated Board, carton,etc.

Cutting material: soft board , kt board , corrugated board, packing box, slotting of corrugated boxes, medium-density material v cuts, carton packaging, hard cardboard, gift boxes,etc.

Cutting materials: sticker, car sticker, reflective materials, self-adhesive vinyl, label, vinyl, engineering reflective film, double-layer adhesives, etc.

Cutting materials: asbestos board, asbestos free board, PTFE, rubber board , fluorine rubber board, silica gel board, graphite board, graphite composite board, etc.

Cutting materials: acrylic MDF board, pvc board, display stand, etc.

Cutting materials: backlit film, sticker, pp paper , folding card, flexible material less than 3mm thickness, advertising materials KT board, flexible plastics, mobile phone film, etc.

Cutting materials: textiles, canvas, leather, fabric, carbon fabric, glass fabric, carpet, blanket, fur, woven fabric, composite double, multi-layer material, flexible plastic, etc.

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109