An aerogel felt vibrating knife cutting machine that helps you solve a variety of problems, cutting a variety of flexible materials, saving a lot of manpower and material resources, keep reading!

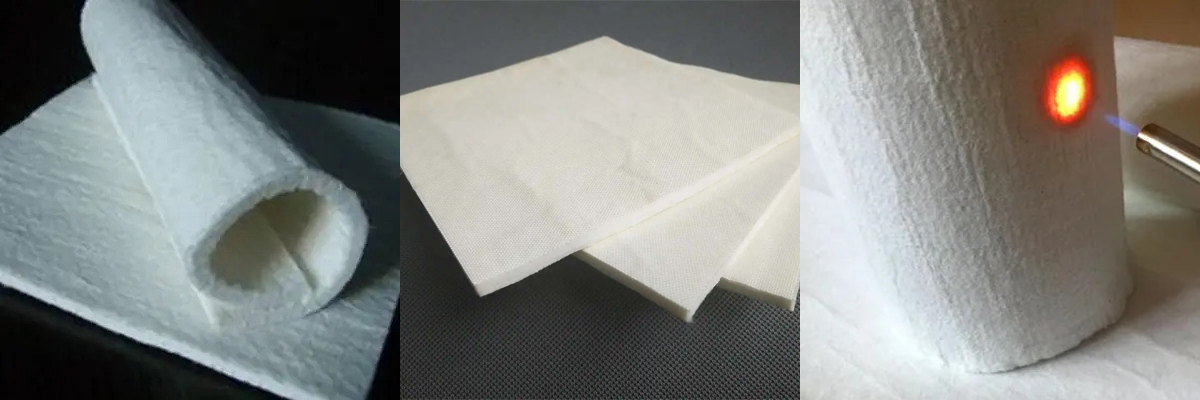

Introduction to Aerogel Felt:

Aerogel felt has a wide range of applications, mature technology and good thermal insulation performance, because of its low thermal conductivity, good thermal insulation effect and high hydrophobicity. Widely used in aerospace and military industry, petrochemical industry, metallurgical building materials, refrigerator cold storage and other fields. Aerogel felt is light in weight, easy to cut and sew to adapt to various shapes of pipes and equipment for thermal insulation, and requires less time and manpower to install.

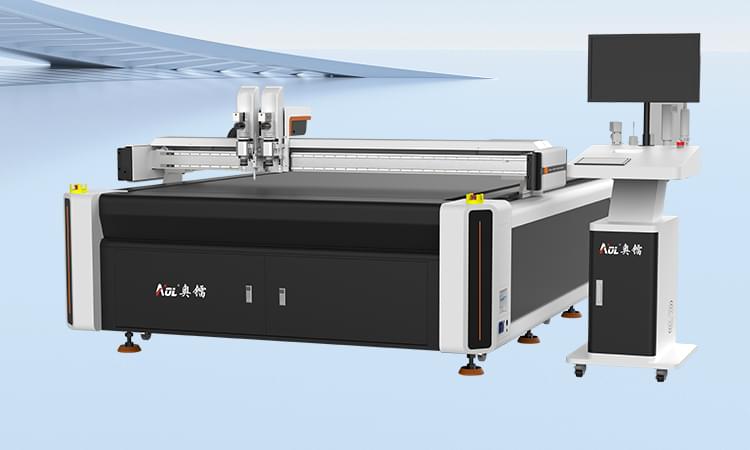

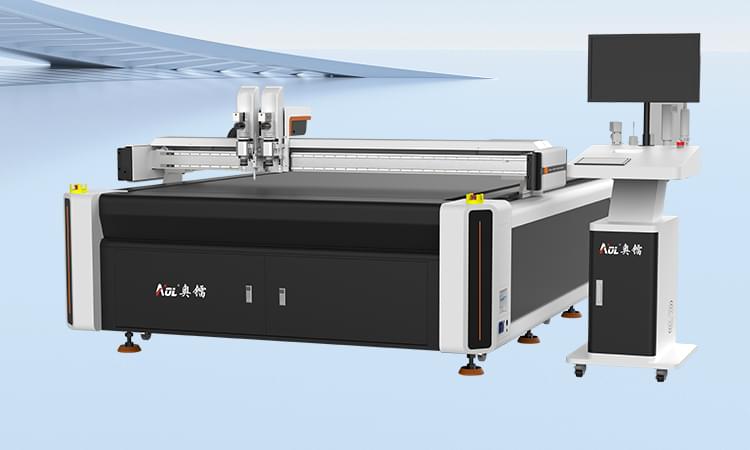

Introduction of Aerogel Felt Cutting Machine:

Aerogel felt cutting It is recommended to use AOL vibrating knife cutting machine. The vibrating knife aerogel felt cutting machine adopts blade cutting, which is not only suitable for nano aerogel felt, but also suitable for rock wool felt, sound insulation felt, carbon fiber felt, carbon fiber felt , glass wool felt and other sound insulation and thermal insulation materials, one equipment can solve dozens of material cutting problems and release labor, which should really reduce production costs and ensure product competitiveness.

AOL automatic aerogel felt cutting machine parameters:

Technical parameters / model |

AOL-1625 |

AOL-1825 |

Effective working area |

1600x2500mm |

1800x2500mm |

Multi-function tool |

Oscillating knife, round knife, pneumatic knife, drag knife, half cutting knife, press wheel, V-CUT Knife Tool, milling cutter, drawing marker pen, ink cartridge inkjet, cursor positioning, camera positioning edge patrol |

|

| safety devices | Four corners emergency stop, anti-collision safety device using infrared induction, safe and reliable |

|

| Cutting tool configuration | Oscillating knife or pneumatic knife or V-CUT Knife Tool | |

Cutting speed |

50-200mm/s |

|

Cutting thickness |

5mm-20mm Other thicknesses can be customized according to the material |

|

Applicable materials |

It can be used to cut Extruded board similar to the material, and different configurations can be selected for different materials. |

|

Material fixing method |

Vacuum partition adsorption |

|

Transmission port |

Network port |

|

Transmission system |

The X\Y axis is divided into two kinds of rack or belt |

|

rated power |

11kw |

|

Rated voltage |

380V±10%/220V±10% Optional |

|

Control System |

Chinese and English LCD touch screen |

|

Operating environment |

Operating environment Temperature 0-40°C Humidity 20%-80%RH |

|

Support file format |

AI、PLT、DXF、PDF、 PCE、XML |

|

| Overall size | 3600x2400x1200mm |

3600x2600x1200mm |

| Other configuration | import servo motor,high precision helical gear reducer,import rail,rack,sensor,low-voltage appliances,power supply, cable,42mm adsorption platform,automatic feeding,rail,energy saving fan | |

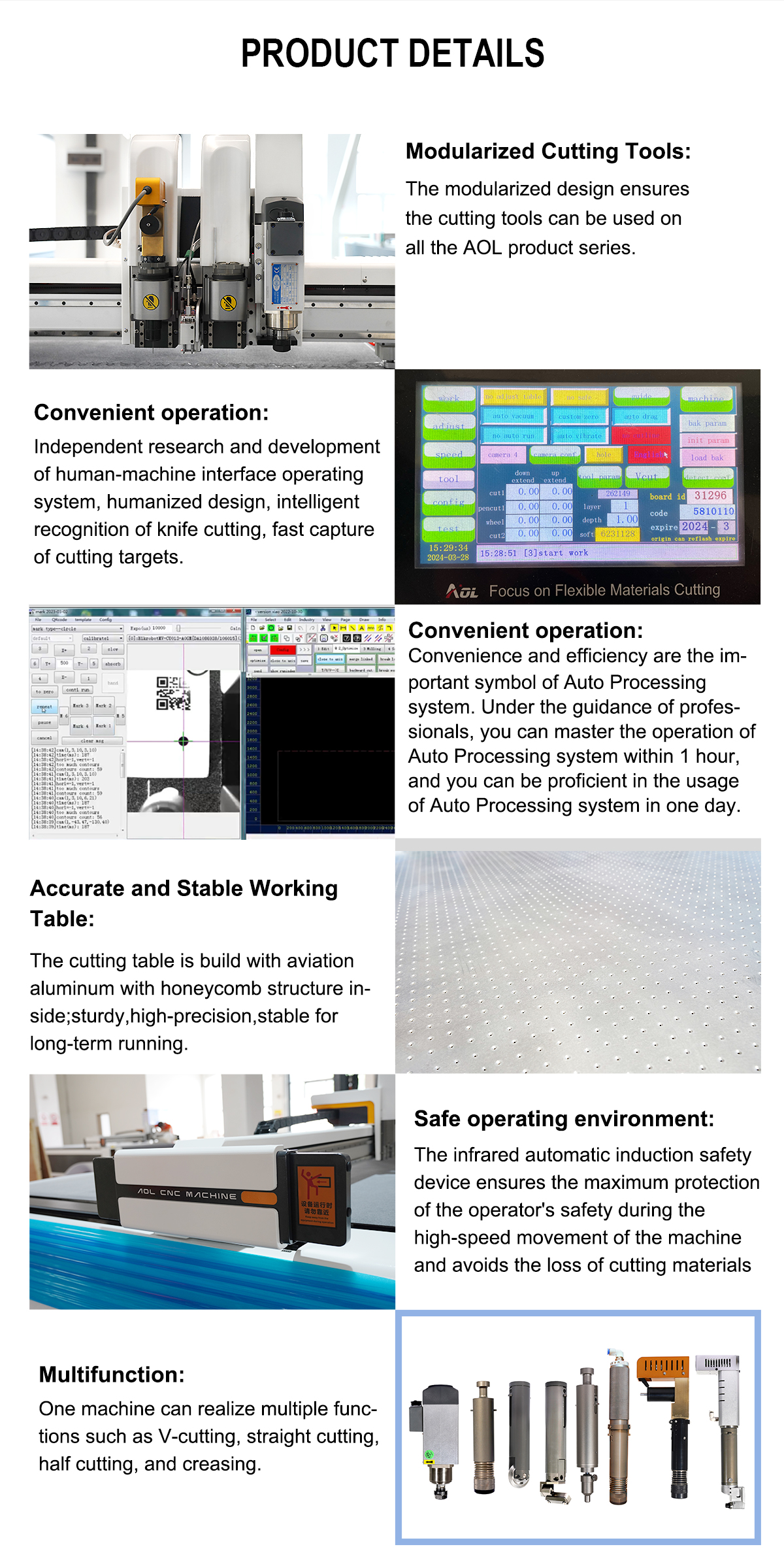

Aerogel felt cutting machine cutting advantages:

1. Powerful functions, the equipment can be equipped with a variety of cutter heads such as vibrating knives, pneumatic knives, drag knives, round knives, etc. One equipment is suitable for hundreds of materials and has a wide range of adaptability.

2. High precision, the equipment adopts pulse positioning system, the positioning accuracy is ±0.01mm, the cutting accuracy is ±0.5mm, and the repeated cutting has zero error.

3. High efficiency, the equipment adopts the whole process of automatic feeding, cutting and unloading, and the running speed can reach 2000mm per second, replacing 4-6 manual workers, and the cutting efficiency is high.

4. Save materials. The equipment has an intelligent typesetting system. Compared with manual typesetting, the equipment typesetting saves more than 15% of materials.

Why choose us:

AOL has been committed to the production and optimization of CNC cutting machines, we have an independent factory, which can fully realize the design, production, sales, delivery and after-sales service process. The whole process is automated, no manual intervention is required, and high-efficiency and high-precision servo motors are used to realize intelligent cutting faster and more accurately. Perfect pre-sale and after-sale service, pre-sale tailor-made plans for you according to the specific situation of your cutting materials, and one-to-one after-sale guidance to ensure that you can master the operation method as soon as possible.

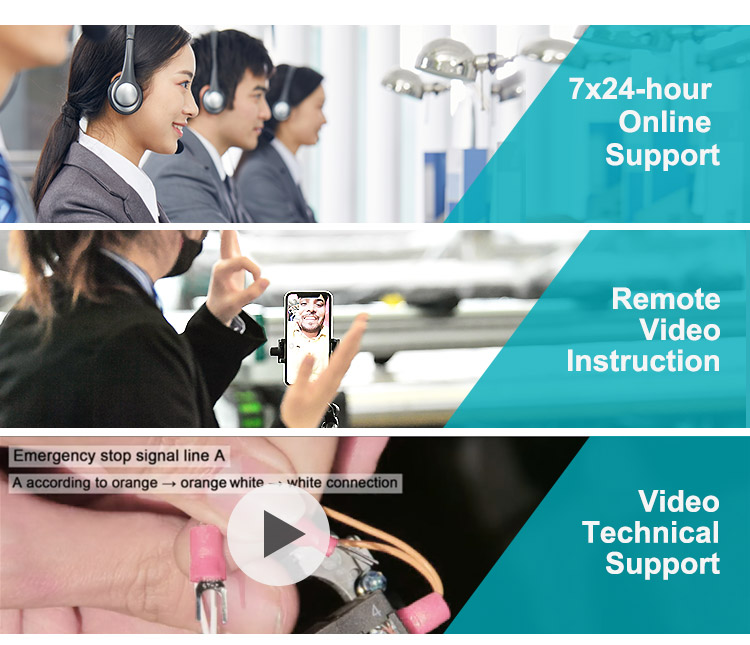

AOL Services:

1) Three-year free warranty (except wearing parts), free inspection and maintenance of main parts.

2) Provide lifetime free technology upgrade service

3) Wearable parts (eg blades, bench covers) are always available at cost when needed.

4) Free operation training in our factory. If there is not enough time, we will send detailed training videos.

5) 24-hour online service, providing free technical support in different languages.

6) On-site technical support is available when needed.

7) AOL accepts unreasonable returns within 7 days after receiving the goods.

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109