The debate between hand cutting and machine cutting has always been a hot topic in fabric production. As technology has advanced, machine cutting has become more and more popular, especially with the advent of computer numerical control (CNC) machines. From the most basic scissors to advanced automatic cutting machines, the process has always been accompanied by a relentless pursuit of precision, efficiency and consistency.

Traditional sofa production relies heavily on hand-cutting and pattern making. This method is time-consuming, requires skilled labor, and often results in inconsistencies. Custom orders make things more complicated because each product requires a unique design, which creates more room for errors and delays.

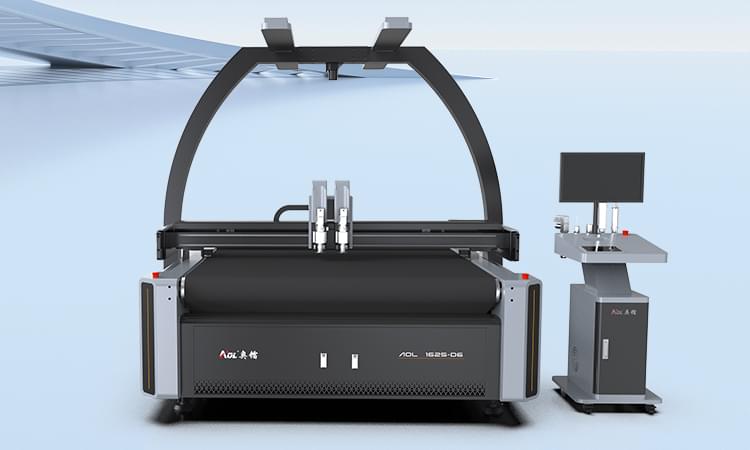

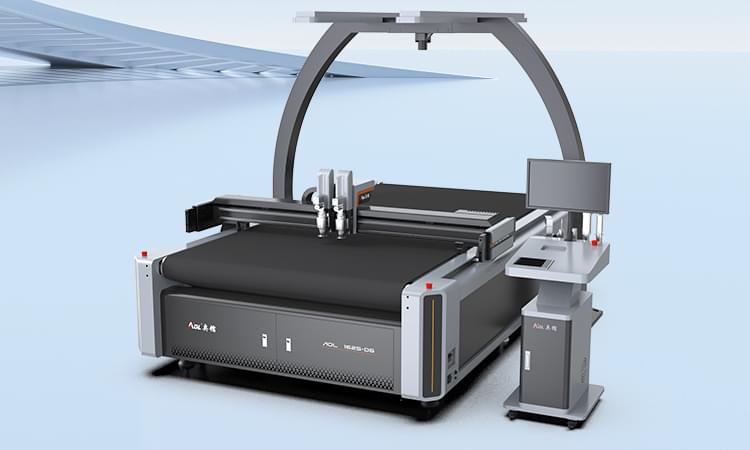

The advent of CNC fabric cutting machines is an advanced manufacturing process that utilizes computer control to operate and manipulate machine tools. This technology allows for precise fabric cutting with only a set of cues. The result is a clean, accurate cut every time.

Parameters of CNC cloth cutting machine:

Technical parameters / model |

AOL-1625 |

AOL-1825 |

| Effective working area | 1600x2500mm | 1800x2500mm |

| Multi-function tool | Pneumatic knife, projector,vibrating knife,Round knife | |

| safety devices | Using infrared sensors, responsive, safe and reliable,Anti-collision system,Four corner emergency stop button | |

| Cutting speed | 300-2000mm/s | |

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |

| Applicable materials | Linen, polyester yarn-dyed knitted fabrics, chemical fiber fabrics, blended fabrics, Hong Kong knitted woolen fabrics, polyester knitted labor fabrics, viscose fiber, leather, acrylic fiber, mulberry silk, spandex, synthetic fiber, man-made fiber, corduroy and other textile fabrics | |

| Material fixing method | Vacuum partition adsorption | |

| Transmission port | Network port | |

| Transmission system | The X\Y axis is divided into two kinds of rack or belt | |

| rated power | 11kw | |

| Rated voltage | 380V±10%/220V±10% Optional | |

| Control System | Chinese and English LCD touch screen | |

| Operating environment | import servo motor, high precision helical gear reducer, import rail, rack, sensor, low-voltage appliances, power supply, cable, 42mm adsorption platform, automatic feeding, rail, energy saving fan | |

| Support file format | AI、PLT、DXF、PDF、 PCE、XML | |

| Overall size | 3600*2400*1250 | 3600*2600*1250 |

Advantages of CNC fabric cutting machine:

1. Production speed and efficiency: CNC cutting machines work continuously 24 hours a day, 7 days a week, greatly improving production efficiency, which is crucial in today's fast-paced manufacturing environment.

2. Accuracy and precision: They provide excellent accuracy. These machines follow preset instructions, eliminating the risk of human error and ensuring that every cut is precise and consistent.

3. Improved scalability: This means that companies can increase production as needed without significantly increasing labor costs.

4. Versatility: CNC cutting machines are able to handle a variety of materials and complex cuts, making them a versatile tool in the manufacturing industry.

5. Consistency: With CNC fabric cutting machines, every cut is exactly the same, ensuring consistency in batch production. This is particularly important in industries where component consistency is critical.

6. Reduced waste: CNC cutting machines run on software and are iteratively optimized to process parts without waste. This not only saves material resources, but also reduces overall production costs.

7. Ease of use: Modern CNC fabric cutting machines come with user-friendly interfaces and automated processes, reducing the skill level required to operate.

By integrating advanced fabric cutting machines into your production line, you gain unprecedented flexibility. Imagine being able to switch from one design to another without pausing production. These machines can even handle complex patterns, so no design is too tricky. In addition, they optimize fabric use, reduce waste and save costs.

AOL company information:

AOL is an industry-leading brand with 14 years of industry experience. We have served more than 8,000 customers around the world and received satisfactory reviews. We have many long-term and stable cooperation customers. We provide personalized industrial material cutting solutions for many customers. If you encounter problems in industrial material cutting, we can provide you with free consultation and consulting services!

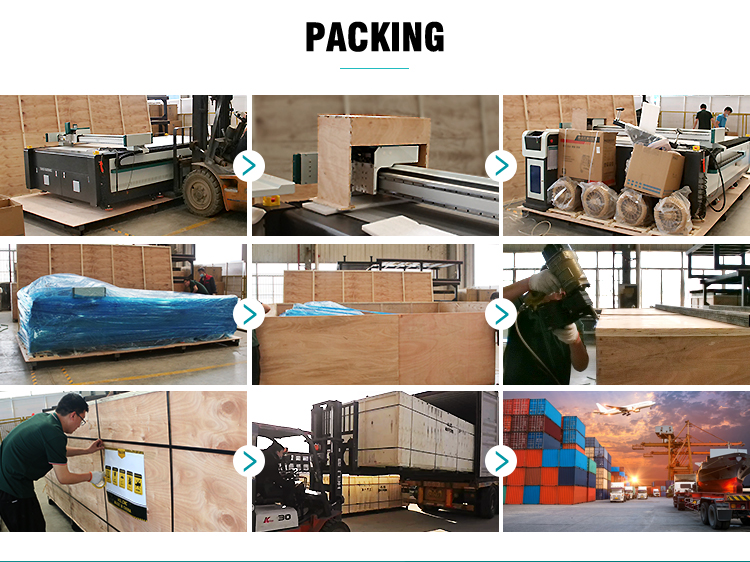

Packaging of the cutting machine:

Outer packing: Standard sea export plywood box.

Inner packing: stretchable film and plastic film to prevent moisture.

If you have special requirements, we can negotiate amicably; if you want to know more, please contact us.

![]() AOL Apparel & Textile Industry Equipment Brochure

AOL Apparel & Textile Industry Equipment Brochure

In the dynamic world of fabric cutting and pattern design, expertise in CNC automated fabric cutting is undoubtedly the key to improving efficiency and accuracy for businesses. Known for its precision and speed, CNC technology has set new standards in the industry, combining speed with reliable accuracy and quality. AOL has been at the forefront of this technological development, demonstrating a long-term commitment to excellence. As experts, their dedication is reflected not only in saving time and reducing errors, but also in optimizing fabric usage and simplifying complex workflows.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcutcnc.com/

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109