PVB film, or polyvinyl butyral film, is a polymer material with high transparency, excellent toughness, and strong adhesion. It is widely used in architectural safety glass, automotive laminated glass, photovoltaic panels, and electronic display screens. PVB film not only enhances the impact resistance and safety of glass, but also provides sound insulation, UV protection, and enhanced visual quality.

Due to its soft texture, easy deformation, and prone to surface adhesion, PVB film places high demands on equipment and processes during cutting.

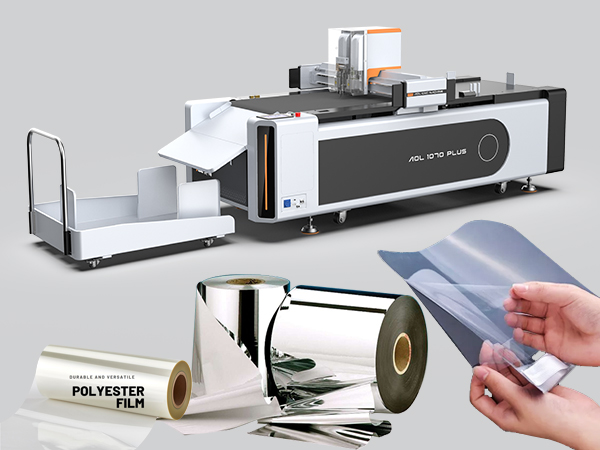

The PVB film cutting machine is a CNC cutting device developed for polyvinyl butyral (PVB) film. Due to its excellent transparency, toughness, and adhesive properties, PVB film is widely used in the production of laminated glass, such as automotive windshields, architectural safety glass, and photovoltaic modules. Traditional manual cutting suffers from low efficiency, poor precision, and edge deformation. However, the PVB film cutting machine utilizes a CNC system and high-frequency vibration or circular knife cutting technology to achieve fast, precise, and damage-free automated processing.

Main features of PVB film cutting machine:

Fully Digital Control System:

Our machines utilize an advanced, fully digital control system to ensure precise cuts every time. This technology reduces errors common in manual cutting, minimizing waste and increasing production efficiency.

High Efficiency:

The fully digitally controlled PVB film cutting machine is designed to optimize workflow and operate at high speeds without compromising quality. Its efficiency translates into faster production cycles, enabling businesses to meet tight deadlines and increase overall output.

Precision Cutting of Any Shape:

A key feature of our machines is their ability to cut PVB film into a wide variety of complex shapes. This versatility is crucial for applications requiring custom designs that meet specific project needs while maintaining high-fidelity shape retention.

User-Friendly Interface:

The machine features an intuitive touchscreen interface, making it easy to operate even for users with limited technical experience. Operators can quickly set up and adjust parameters and monitor the cutting process in real time, making it easy for all personnel to use.

Rugged Construction:

Our cutting machines are designed to withstand the demands of continuous operation, featuring a durable design and high-quality materials for increased lifespan and reliability. This robustness ensures the machines can handle high-volume production without requiring frequent maintenance.

Advanced Safety Features:

Safety is paramount in any manufacturing environment. This fully digitally controlled PVB film cutting machine is equipped with numerous safety features, including an emergency shutoff switch and safety cover, to protect operators and minimize risks during operation.

Customizable Software Solutions:

This machine features customizable software for integration with existing production systems. This compatibility facilitates seamless data transfer and workflow integration, ensuring your production process is as efficient as possible.

Energy-Efficient Design:

With sustainability at the forefront, our machines are designed with energy efficiency in mind. Their operating parameters are optimized to reduce energy consumption, helping businesses maintain peak performance while lowering operating costs.

Excellent After-Sales Support:

We pride ourselves on providing exceptional customer service. Our team of experts is always available to provide technical support, training, and maintenance advice, ensuring you get the most out of your investment in our cutting-edge technology.

The fully digitally controlled PVB film cutter is versatile and suitable for a wide range of applications, including:

Automotive: Ideal for cutting PVB films used in automotive windows and windshields, ensuring safety and clarity.

Architectural Glass: Ideal for manufacturing laminated glass for contemporary architecture, where design flexibility is crucial.

Electronics: Facilitates the production of high-quality protective screens and layers for electronic devices.

Custom Manufacturing: Tailored for businesses across various industries requiring customized products cut to specific shapes.

In summary, our fully digitally controlled, efficient, and precise PVB film cutting machine is an ideal solution for manufacturers looking to increase productivity without sacrificing quality. Combining modern technology, rugged design, and user-friendly operation, this machine ensures reliability while empowering innovation.

PVB film cutting machines are essential equipment in the modern glass processing industry, ensuring high precision and efficiency while improving material utilization and product quality. They are particularly suitable for automotive glass, architectural glass, and photovoltaic module manufacturers, providing intelligent, flexible, and environmentally friendly solutions for production.

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcutcnc.com/

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109