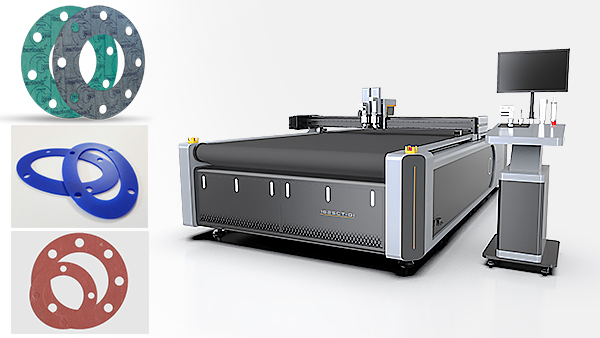

In recent years, rubber gasket cutting machines have become an increasingly important tool in industrial applications. These machines offer a reliable and cost-effective method of cutting rubber gaskets, increasing efficiency, reducing costs, and improving the accuracy of gasket cutting.

Another benefit of using a rubber gasket cutter is its increased safety and efficiency. Manual cutting can be dangerous because it requires handling sharp blades and other tools. On the other hand, a rubber gasket cutter is fully automatic, requiring little to no human intervention and is much safer than traditional cutting methods. Furthermore, a rubber gasket cutter can be programmed to quickly and accurately cut multiple gaskets at once, significantly reducing the time and effort required during the cutting process.

Finally, a rubber gasket cutting machine is more cost-effective than traditional cutting methods. By eliminating labor and reducing cutting time, a rubber gasket cutting machine can significantly reduce costs. Furthermore, the higher precision of the cutting process can reduce subsequent problems, thereby reducing the need for costly repairs or replacements.

In short, rubber gasket cutting machines are an indispensable tool in industrial applications. They offer a safer and more efficient way to cut rubber gaskets, helping to reduce costs, improve precision, and increase productivity. For this reason, rubber gasket cutting machines are becoming increasingly popular in the industrial sector.

Impact of Automatic Gasket Cutting Machine on Productivity and Efficiency:

Automatic gasket cutting machines are revolutionizing the way companies produce gaskets. By automating the cutting process, these machines are helping businesses across various industries increase productivity and efficiency.

The introduction of automated gasket cutting machines has significantly improved the speed and accuracy of the gasket cutting process. By eliminating the need for manual labor, companies are able to significantly reduce the time and resources required to produce gaskets. Automated machines also produce higher-quality products than manual machines. This not only provides customers with more reliable products but also improves the company's efficiency.

The cost savings offered by automated gasket cutting machines are also significant. By eliminating the need for manual labor, companies can reduce both labor costs and operating expenses associated with producing gaskets. Furthermore, automated machines produce more consistent and reliable products, leading to fewer returns and lower costs for the company.

Finally, automated gasket cutting machines offer businesses greater flexibility and scalability. By automating the cutting process, businesses can quickly and efficiently scale up production to meet demand. This increased flexibility allows businesses to quickly respond to changes in market and production demands, improving operational efficiency.

How to choose the right rubber gasket cutting machine for your business?

Choosing the right rubber gasket cutting machine for your business can be daunting. It's important to understand the features and capabilities of the various machines so you can choose the one that best meets your needs.

The first step in choosing the right rubber gasket cutting machine is to determine what type of rubber gasket you need to produce. Different machines have different capabilities, so it's crucial to understand the specific shape, size, and thickness of the gasket you need to produce. Knowing the exact specifications of the gasket you need will help you narrow down your machine selection.

Another key point is to determine the cutting speed and accuracy required for your application. Many machines offer different cutting speeds and accuracies depending on the type of rubber gasket material you are using. If you require precise cuts, a CNC machine may be the best choice. However, if you need to cut multiple gaskets quickly, you may want to choose a machine with a faster cutting speed.

Finally, you need to consider the cost of the machine. Rubber gasket cutters can range in price from a few hundred dollars to several thousand dollars. Choosing a machine that fits your budget while providing the features and performance you need is crucial.

By carefully considering the type of rubber gaskets you need to produce, your cutting speed and accuracy requirements, your power source, and your costs, you can choose the right rubber gasket cutting machine for your business. With the right machine, you can ensure your gaskets are produced with high precision and accuracy, saving you time and money.

As the manufacturing industry's demand for efficient, precise, and flexible production continues to grow, CNC rubber gasket cutting machines have become an ideal solution for solving complex cutting challenges. They not only transcend the limitations of traditional processes, achieving both high precision and high efficiency, but also help companies save costs and enhance their competitiveness. Whether for single-piece customization or large-scale production, CNC cutting technology is injecting new impetus into the rubber gasket industry.

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcutcnc.com/

No.5789, Yushan Road, Jinan City, Shandong Province, China

No.5789, Yushan Road, Jinan City, Shandong Province, China +86 18560162709

+86 18560162709 250109

250109